Starting in 1979, as one of the original companies on what is now the Cambridge Science Park, Noblelight, (now Heraeus Noblelight), has been rooted in innovation and product development from inception. Originally founded with only three employees, Noblelight began by focusing on and developing excitation lamps for lasers.

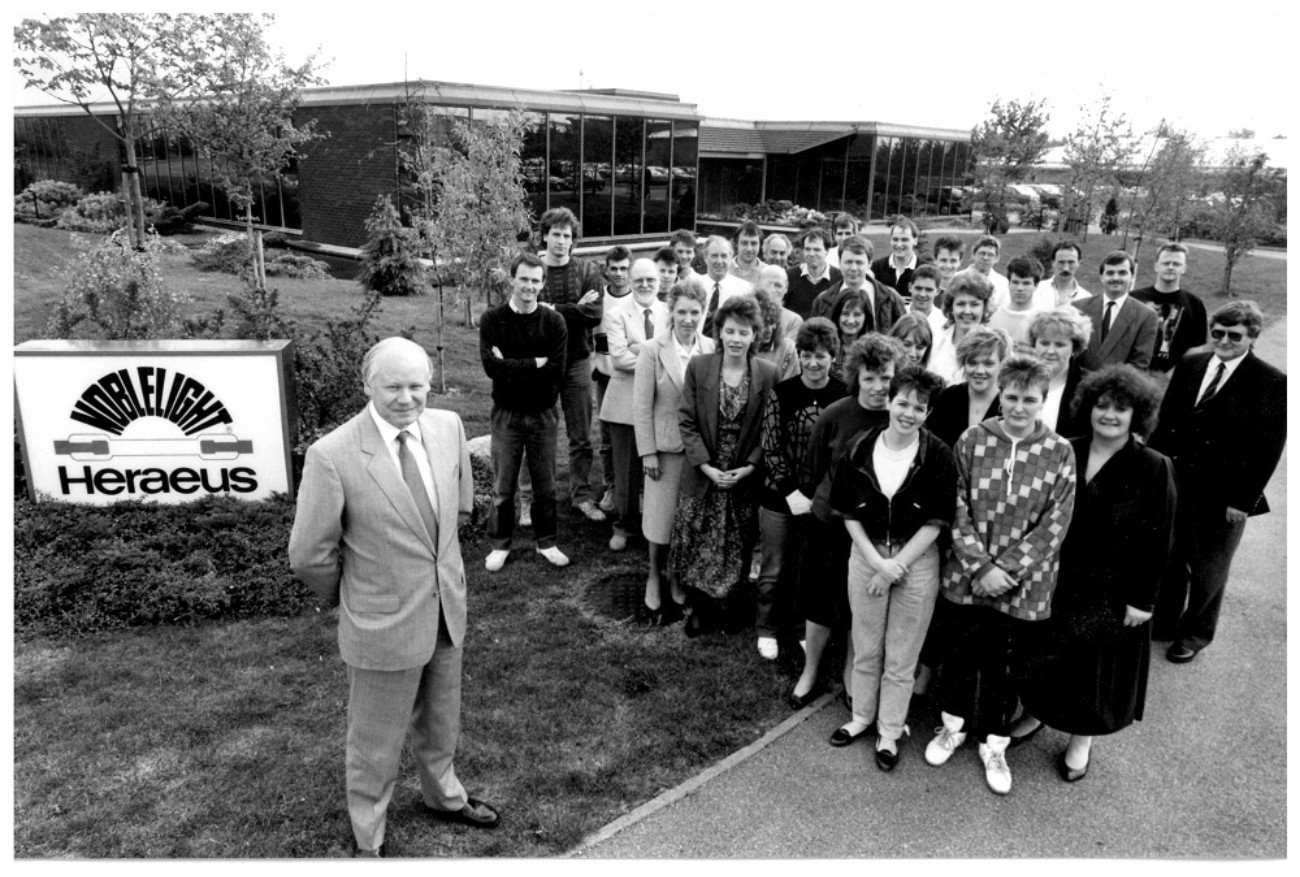

In 1987 the company became a part of the Heraeus Group, which has been delivering advanced technologies across the globe for more than 160 years. This new ownership provided stronger financial backing and access to advanced lamp manufacturing technology including quartz glass expertise.

The growing usage of lasers for research and industrial applications, drove rapid market and product development. Heraeus Noblelight developed the first “long life” continuous laser lamps, named the Supalamp Series. This brought the benefit of significantly increased operating life from utilising flash lamp technologies to the mass market, and intern drove the expansion of new industrial customer application areas. Over the last fifteen years we have developed our own automated flash lamp manufacturing processes. As a result, we are proud to have received the Queen’s Award for Enterprise three times, most recently in 2015. These pioneering processes improved quality and operating life to such a degree that flash lamps now see continued use in applications previously predicted to lose out to other technologies.