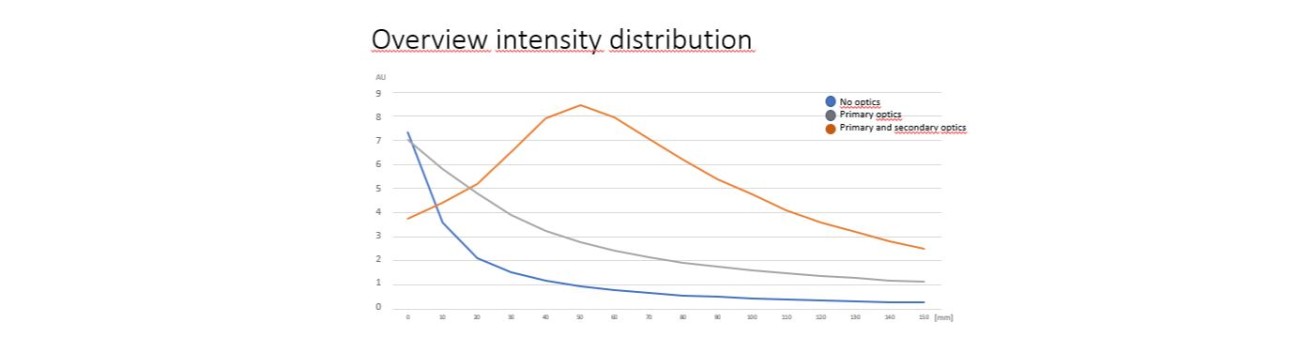

No Optics

An LED chip is a not a spot source (different from a laser), but a surface emitting diode. Therefore the emitting light will spread at an angle of 120°. Processes that are run close to LEDs (0-20mm) will not be impacted by this, but the further a process moves away from the light source the stronger the effect of diffusion will become.