Inefficient mixing and application systems can result in inconsistent cement, unpredictable cement polymerization times, longer OR times, and other inefficiencies. Our PALAMIX® cartridge vacuum mixing system is designed to produce consistent, homogeneous cement; and when paired with our design-winning cement application gun - minimizes cement wastage. Optimized mixing and application... You'll see the advantages add up.

PALAMIX® Cartridge Vacuum Mixing System

Cartridge Vacuum Mixing System for Safety and Simplicity

Standardize Your Cement Portfolio with PALAMIX®

The PALAMIX® mixing system is designed to enable easy preparation and delivery of high quality bone cement:

- Consistent results due to standardized mixing process

- Particle filter prevents glass particles from entering the bone cement

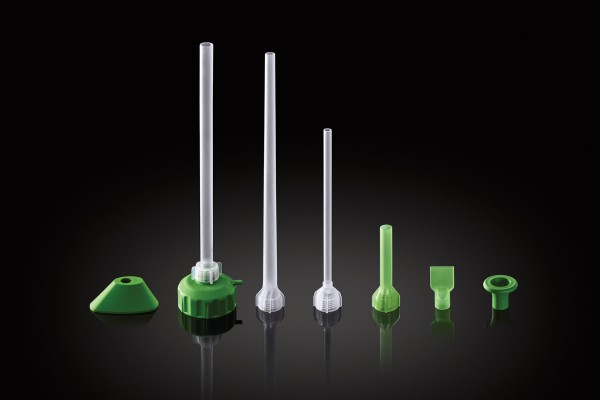

- Diverse selection of nozzles and pressurizers for optimal application

- Mix up to two pouches of bone cement (2x40) in PALAMIX® uno, or up to four pouches (4x40) in PALAMIX® duo.

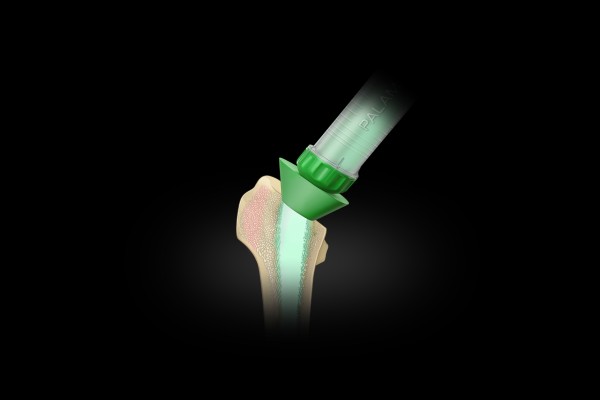

- Apply bone cement directly from the mixing cartridge

- PALAMIX® has been shown to be 30 percent more effective at extruding cement than StrykerTM mixing systems – a cost savings of up to $3501,2

Air-induced porosity within the cement mantle can lead to a rapid propagation of fractures, weakening the cement mantle. A fractured and fragile cement mantle compromises the integrity of the interfaces, and therefore the survivorship of the implant.3 Vacuum mixing reduces porosity, improves cement homogeneity, and strengthens the cement-prosthesis interface.4

Conventional mixing has been shown to substantially increase the likelihood of micro- and macrovoids in the cement mantle.5 These increases of micro- and macrovoids (radiolucent lines under x-ray) have been linked to aseptic loosening in TKA.6

Conversely, vacuum mixing has been shown to decrease void area and increase cement density5, leading to stronger cement and increased overall survivorship.

Mixing and Collecting

With PALAMIX® the mixing of the components and the collection of the bone cement is carried out under vacuum. This not only facilitates mixing and saves preparation time before application, but also reduces porosity.7

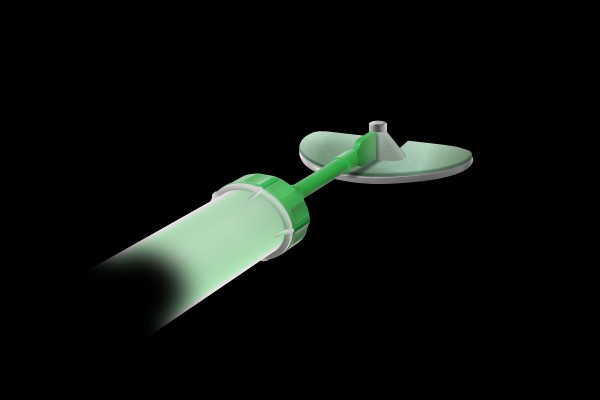

Applying and Pressurizing

PALAMIX® provides various options for application and pressurization of bone cement. Different nozzles are available for individual procedures and allow flexibility in surgery. With PALAMIX®, it is even possible to expel the mixed bone cement remaining in the nozzle, thereby minimizing cement waste.

Pressurization results in greater penetration of the bone, improved bone cement interface and increased fatigue strength of the cement.8

1 Horas U, et al. Factors influencing the application of vacuum mixing systems for bone cement completion. Osteo Trauma Care 2002; 10(2): 106-12.

2 Data on file.

3 Wang: the benefits of vacuum mixing, in Breusch et al. The well-cemented total hip arthroplasty. 1998;108.

4 Wang: the benefits of vacuum mixing, in Breusch et al. The well-cemented total hip arthroplasty. 1998;111.

5 Wilkinson JM, et al. Effect of Mixing Technique on the Properties of Acrylic Bone-Cement. J Arthroplasty 2000; 15(5): 664-7.

6 Hampton CB, et al. Aseptic Loosening at the Tibia in Total Knee Arthroplasty: a Function of Cement Mantle Quality? J Arthroplasty 2020; ePub Ahead of Print.

7 Wang: The Benefit of Vacuum Mixing. In: The Well Cemented Total Hip Arthroplasty 2005. Springer Verlag; 107–112.

8 Wang. Femoral Pressurisation. In: The Well Cemented Total Hip Arthroplasty 2005. Springer Verlag; 160–163.

9 Data on file.