Fusion UV® - UV Application Competence Center

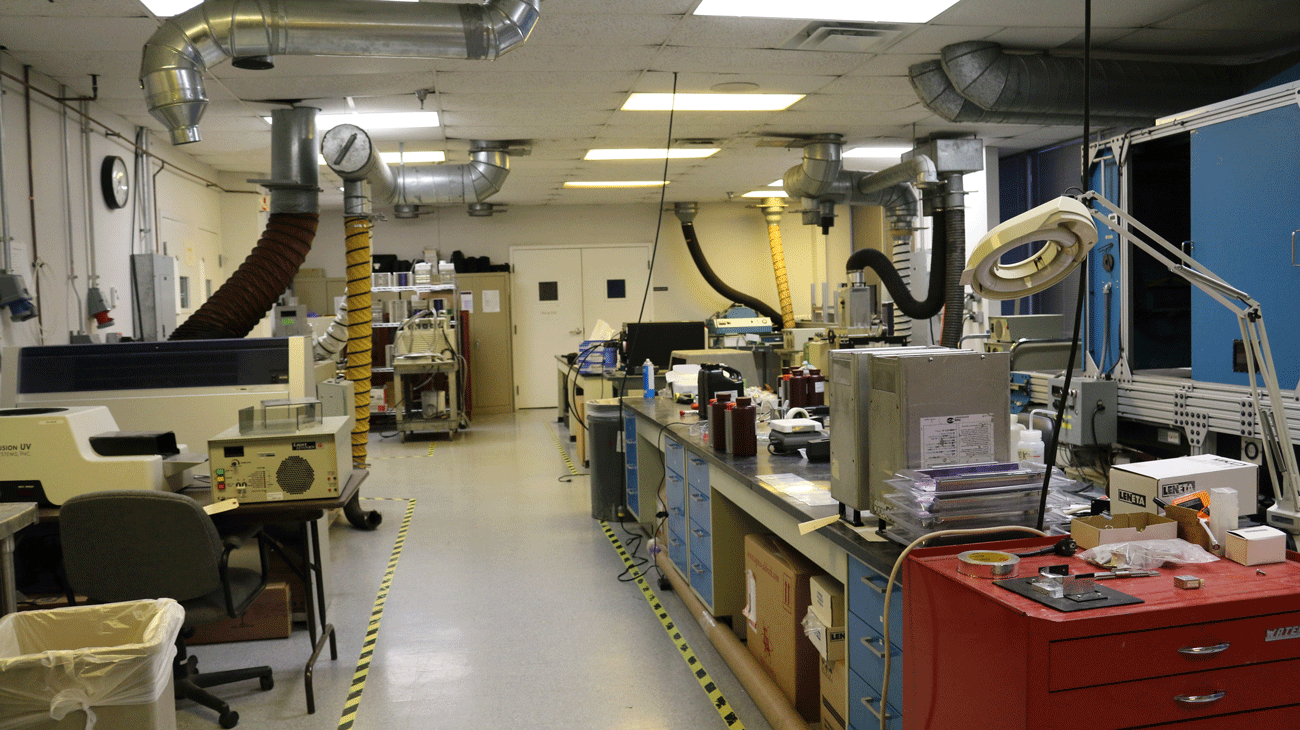

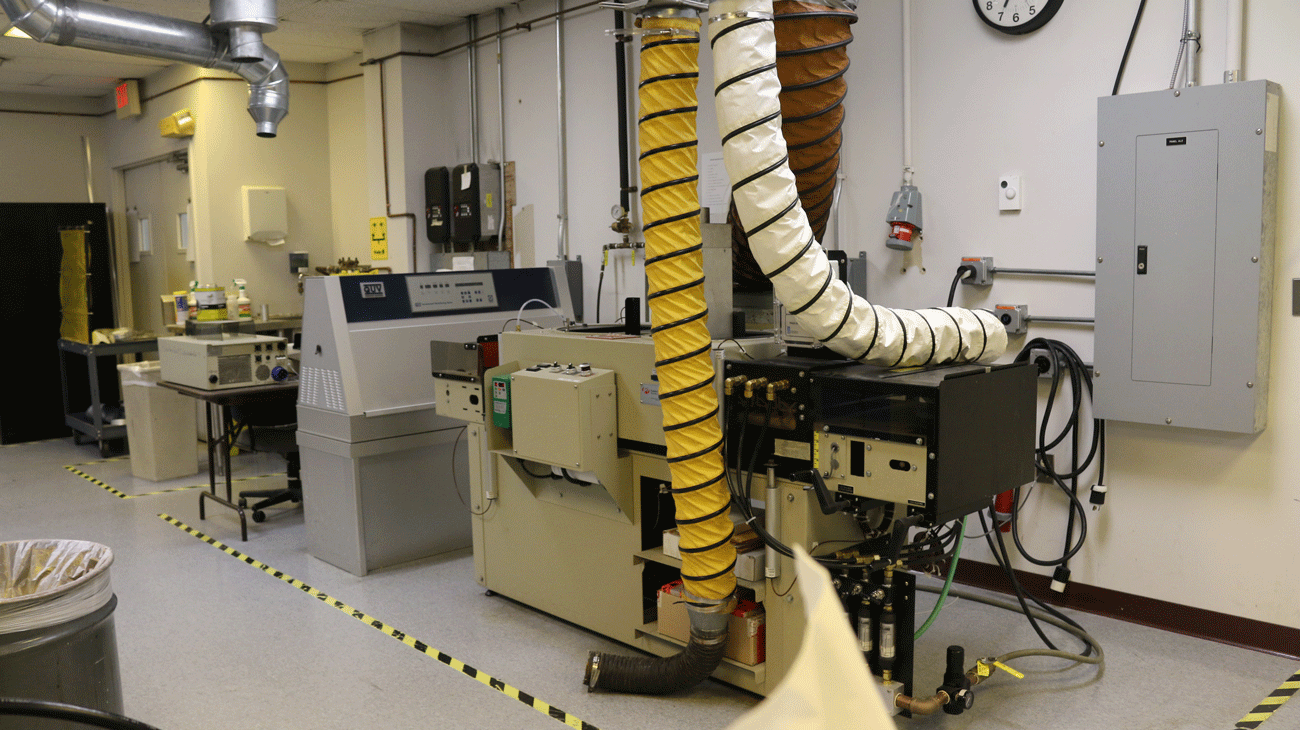

Our Application Competence Centers (ACCs) are the perfect place to field-test UV curing in a real-life setting. No need to tie up critical production lines in your plant. Noblelight America’s ACCs replicate the plant environment without compromising confidentiality. Rely on our UV curing application specialists in Maryland and California to work alongside you to conduct laboratory testing – from start to finish.

Some of the services we offer include:

- Feasibility testing for new UV curing processes

- UV curing process design & optimization

- UV curing process validation testing

- Analytical evaluation of cure & physical properties

Prospects and customers find our application laboratories the perfect place to develop manufacturing processes. By applying and curing formulated UV coatings, inks and adhesives on a variety of substrates, we determine the optimal lamp configuration and part movement. We’re able to quantify and optimize depth and rate of cure, maximizing process speeds and product quality. While there are no fees for occasional use of our ACC, we do ask that you schedule visits in advance.

For large scale, production-like UV trials, we can arrange a UV trial at a facility that will meet your production process needs. Or for trials in your plant, we loan out UV curing equipment for testing on your line.

| Typical project stages and how we can assist: | |

|---|---|

| Feasibility/Initial Investigation | We can help you learn the basics about UV curing and provide contacts for chemistry, line integrators and automation machinery. Often we also provide ballpark UV system investment costs, estimate production rates, energy savings, and other information helpful for an initial return on investment (ROI) analysis. Some basic level of testing confirms product requirements can be met along with estimates of production rates. |

| Determine Processing Parameters |

Once the project passes the feasibility stage, most customers need to determine in detail how the UV curing process will fit into their overall manufacturing production. We typically provide lab testing, radiometry measurements training, and process design assistance. If needed, full scale testing is also possible: • numerous pilot lines have Noblelight America UV curing equipment • we have UV curing equipment available for line trials in your own facility The information gained in this stage enables you to be certain the UV curing process will meet your needs, and provide the ROI or other business objectives desired. |

| Post Implementation | Once a UV curing production line is up and running we often answer questions about radiometry measurements for UV process and quality control and assist our customers with developing appropriate procedures. |

The chart below lists the testing capabilities that are available at each US American site based on the type of equipment and the application tools.

| Gaithersburg, MD | Torrance, CA | |

|---|---|---|

| Conveyers | ||

| Floor Standing Conveyor (DRS) | ■ | |

| Bench Top Conveyor (LC6B) | ■ | ■ |

| Nitrogen Inerted | ■ | |

| Custom Conveyers | ■ | ■ |

| UV Lamp Systems | ||

| Microwave (F300, LH6, F450, F600, LH10) / Fusion UV Systems | ■ | ■ |

| LED (Semray, IRIS, Altair) | ■ | ■ |

| Low Pressure Arc (UVC Cure) | ■ | |

| Radiometry | ||

|

Examples: EIT PowerPuck II, LEDCure, MicroCure, UVICure Plus II, Opsytec Dr. Grobel RM-12 |

■ | ■ |

| Application Tools | ||

| Wet Film | ■ | ■ |

| Printing | ■ | ■ |

| Spray | ■ | |

| Ovens/Stationary Treatment | ||

| Convection Oven | ■ | ■ |

| 3D Curing Chamber | ■ | |

| General Testing | ||

|

Examples: Temperature, Film Thickness, Hardness, Cure Depth, Gloss, Color Density |

■ | ■ |