Heraeus medical device housings are recognized world-wide for their innovative design and manufacturing excellence.

- As the only company 100% dedicated to the medical device market, Heraeus is uniquely qualified to tackle our customers’ most complex and important projects.

- We can offer integrated solutions, including rapid prototyping, to help customers address their specific housing challenges.

- Our housings are built with the most advanced tool and die design, best suited to run the high-tech materials our customers use in their device design.

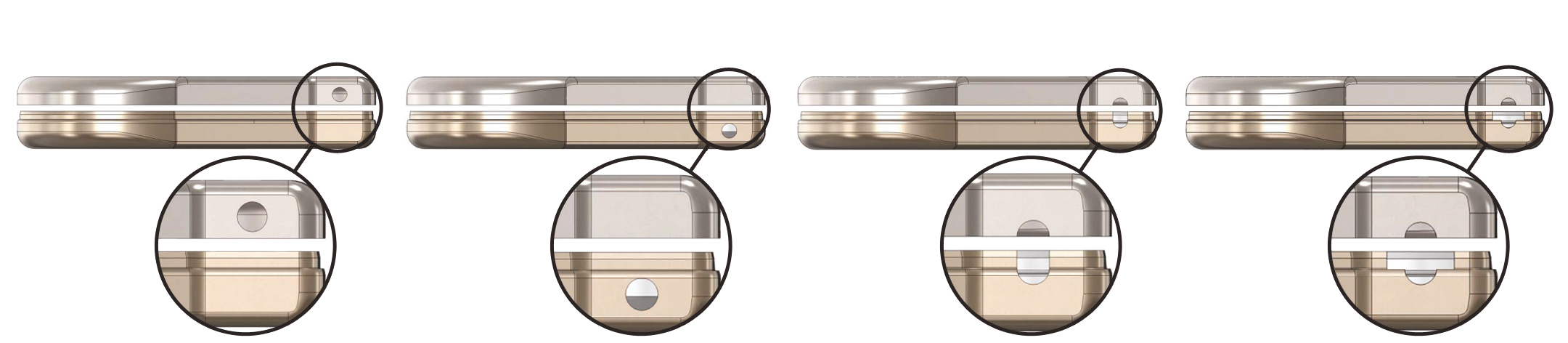

- The special integrated weld band concept produces a device that has a flawless design and finished look that reflects your high standards of quality.

- Every finished housing is perfectly manufactured with our world-class engineering and innovative manufacturing processes.

Every housing we manufacture is designed for the ultimate in durability, reliability, safety and performance. From prototype to inspection development to finished product, Heraeus provides customers with excellence and innovation every step of the way.