Heraeus High Performance Coatings is pleased to announce the minimization of an innovative solution for gaps in laminated rare-earth-metal magnets for next gen electromotor construction.

Enhanced E-Motor Efficiency: Heraeus Unveils Ultra-Thin Gap Solution for Laminated Rare Earth Magnet Coating

Innovative Coating Technique using a ceramic/epoxy composite Enhances Performance and Manufacturing Efficiency of Laminated Rare Earth Magnets

Hanau, January 19, 2024

This advanced method significantly minimizes the gap between laminated rare earth magnets >50µm to a precise range of 2-8µm.This development represents a substantial advancement in manufacturing efficiency and magnet performance, crucial for high-power electric motors in the e-mobility industry.

This innovative process synergistically merges the adhesive characteristics of epoxy with the electrical insulating properties of ceramic, establishing an ultra-thin interlayer within the magnet segments. By streamlining the reassembly of magnets after cutting, this approach optimizes manufacturing workflow and omitting the glue application. The unique composite coating solution offered by Heraeus simplifies process complexity and enhances production efficiency, ensuring the effective elimination of eddy currents.

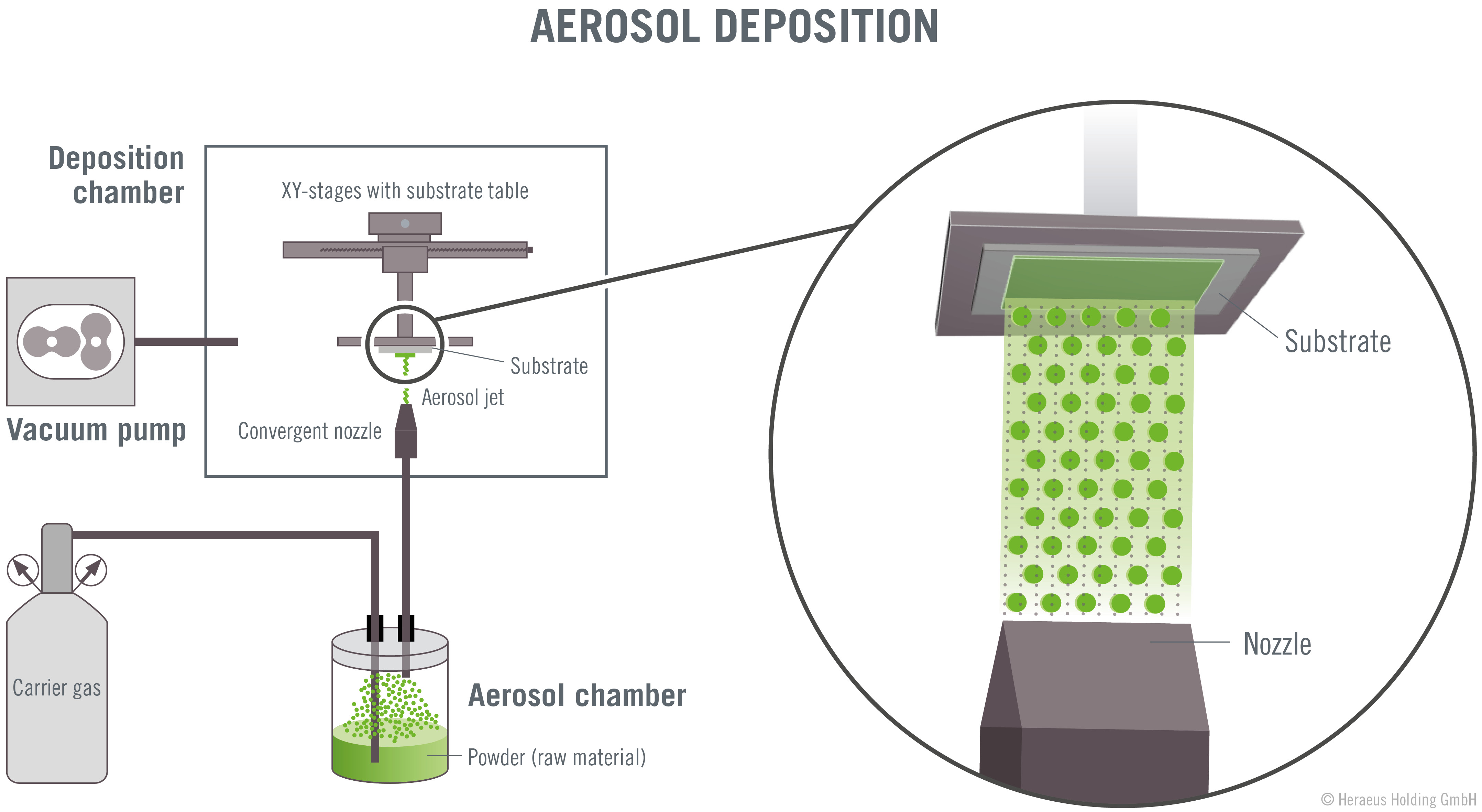

Utilizing the exclusive Aerosol Deposition (AD) method, our solution achieves outstanding gap minimization. Upon thermal activation, this method ensures robust adhesion while maintaining exceptionally narrow gaps, surpassing the capabilities of conventional manufacturing methods such as Glass Sphere Spacer, Thick Epoxy Coating, and Spray Paint Coating. Heraeus' innovative approach is poised to redefine electric motor performance in the e-mobility sector, marking a significant breakthrough in electromotor manufacturing technology.

Manufacturing Advantages:

- Ultra-Thin Composite Layer: Approximately 3µm, combining insulation and gluing in one step, leading to significant cost savings.

- One Coating Step: Streamlined manufacturing process through elimination of a gluing step.

- Economical Production: Single-step, ultra-thin coating potentially lowers production costs by reducing material usage and shortening production time.

- Adaptability: The solution accommodates various magnet shapes and sizes, increasing design flexibility and application in different motor types and sizes.

- Scalability: The technique can be easily scaled to meet varying production volumes, catering to the demands of a growing market.

Performance Advantages:

- Smaller Gap: More magnetic material per volume, enhancing the intrinsic efficiency of the magnets.

- Improved Thermal Stability: The ceramic part of the coating is highly stable at elevated temperatures broadening the application range of the magnets.

- Electrical Insulation: Enhanced electrical insulation between laminated layers, suppressing eddy current losses and boosting effective magnetic flux density.

Sustainability Advantage:

- Eco-Friendly: Absence of wet chemical processes and VOC emissions underscores the environmentally friendly aspect of the AD method.

"This innovative coating technique by Heraeus opens up new horizons in e-mobility, significantly enhancing the efficiency and performance of electric motors. The reduced gap in stacked rare earth magnets is a game-changer in motor design, aligning perfectly with our industry's goal for higher motor efficiency and sustainability.", states Dr Ilka Luck, Head of Heraeus High Performance Coatings.

This advancement aligns with the escalating demand for superior and efficiently manufactured rare earth magnets, crucial for the burgeoning e-mobility sector. The AD method serves as a beacon of innovation, addressing the pressing needs of magnet manufacturers in Japan and beyond. Automotive developers and technicians responsible for introducing new technologies are encouraged to explore the potential of this innovative method to meet the evolving demands of the e-mobility sector.

Contact us to get further information about AD coating process that uses a carrier gas to accelerate material particles at room temperature to a speed of several hundred meters