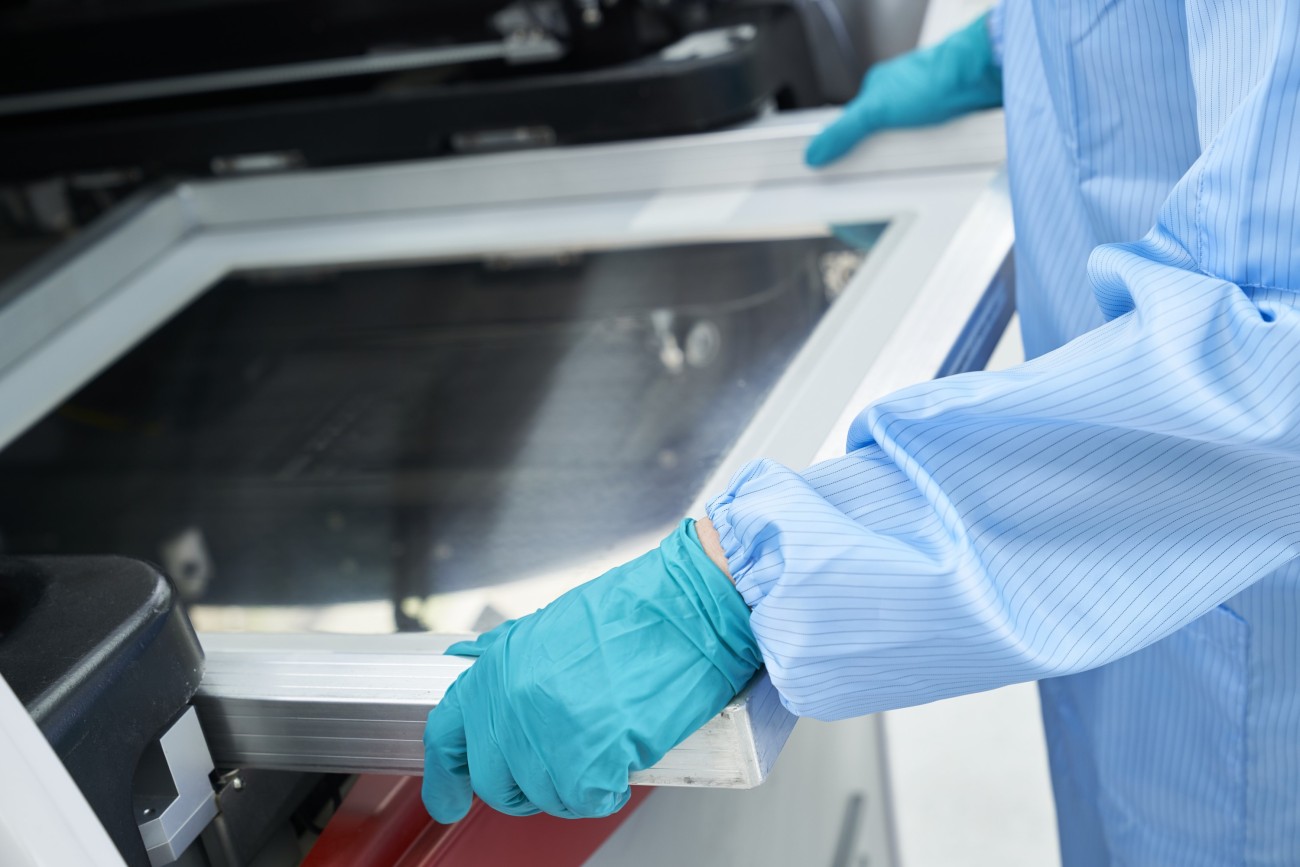

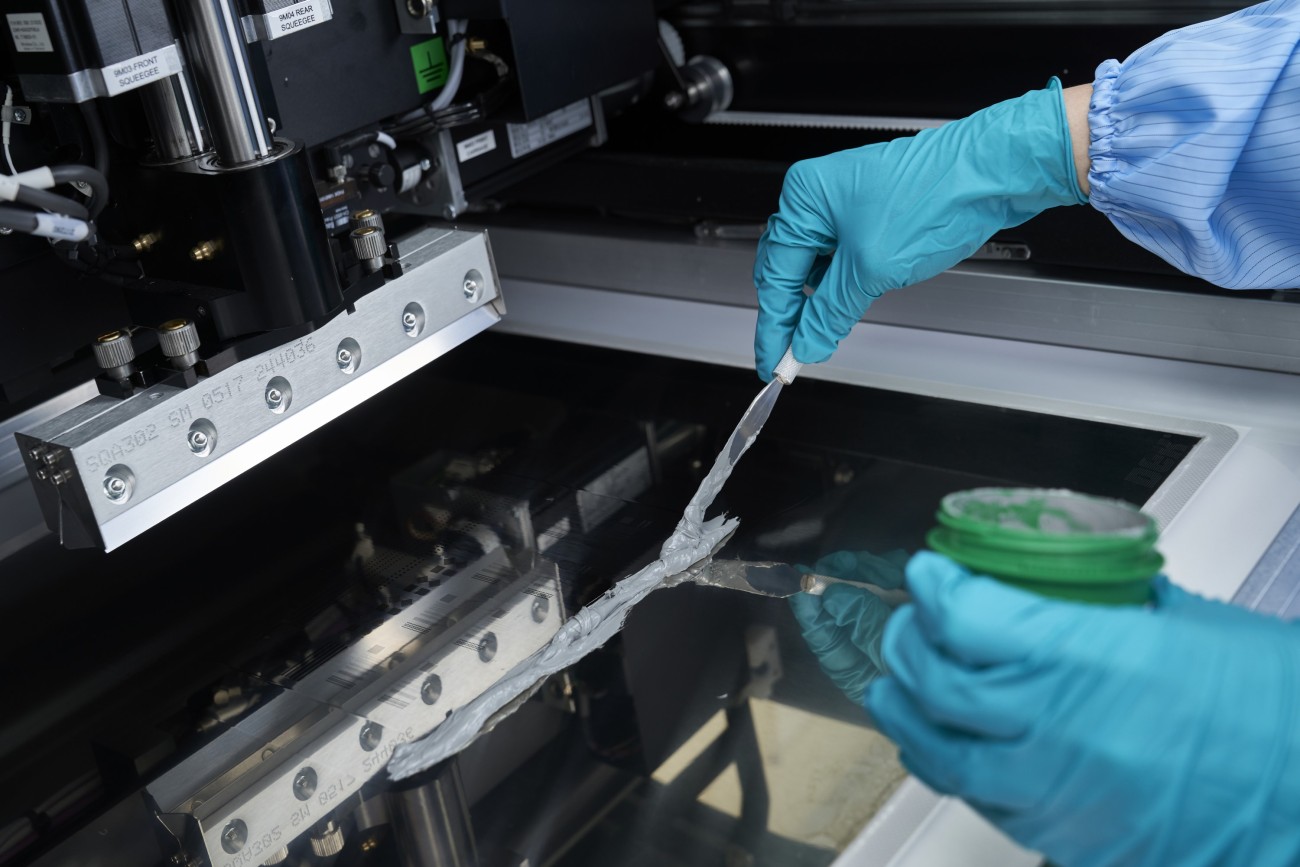

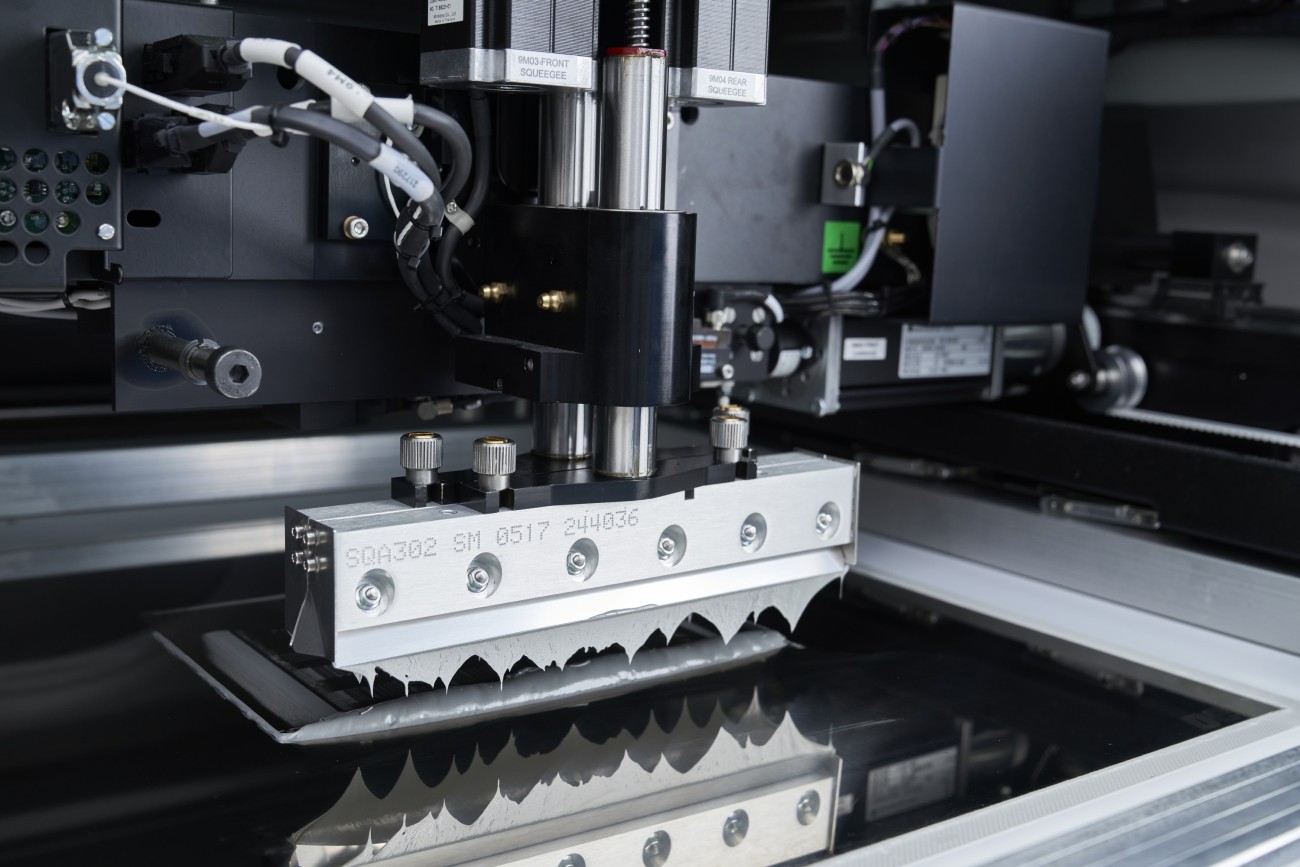

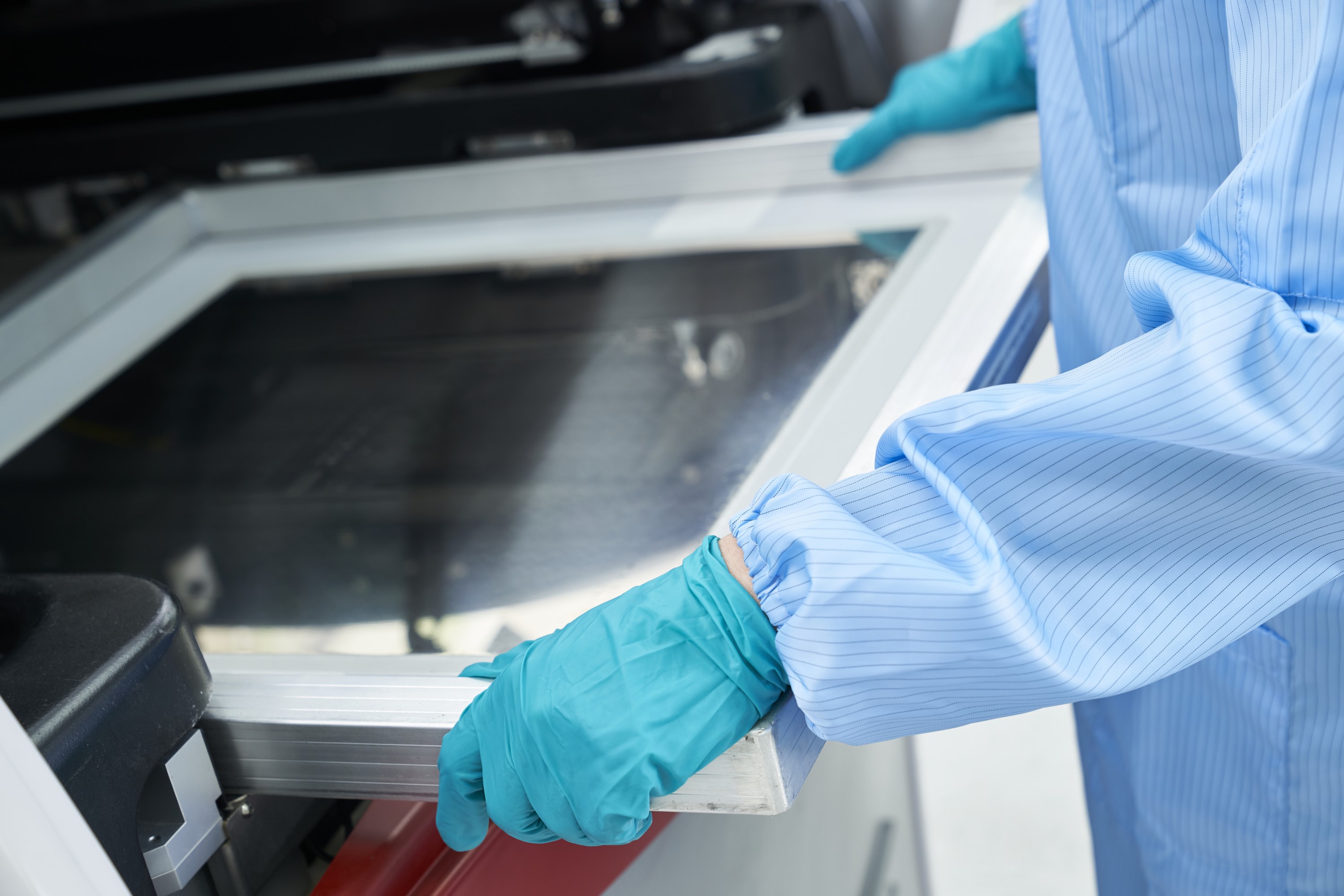

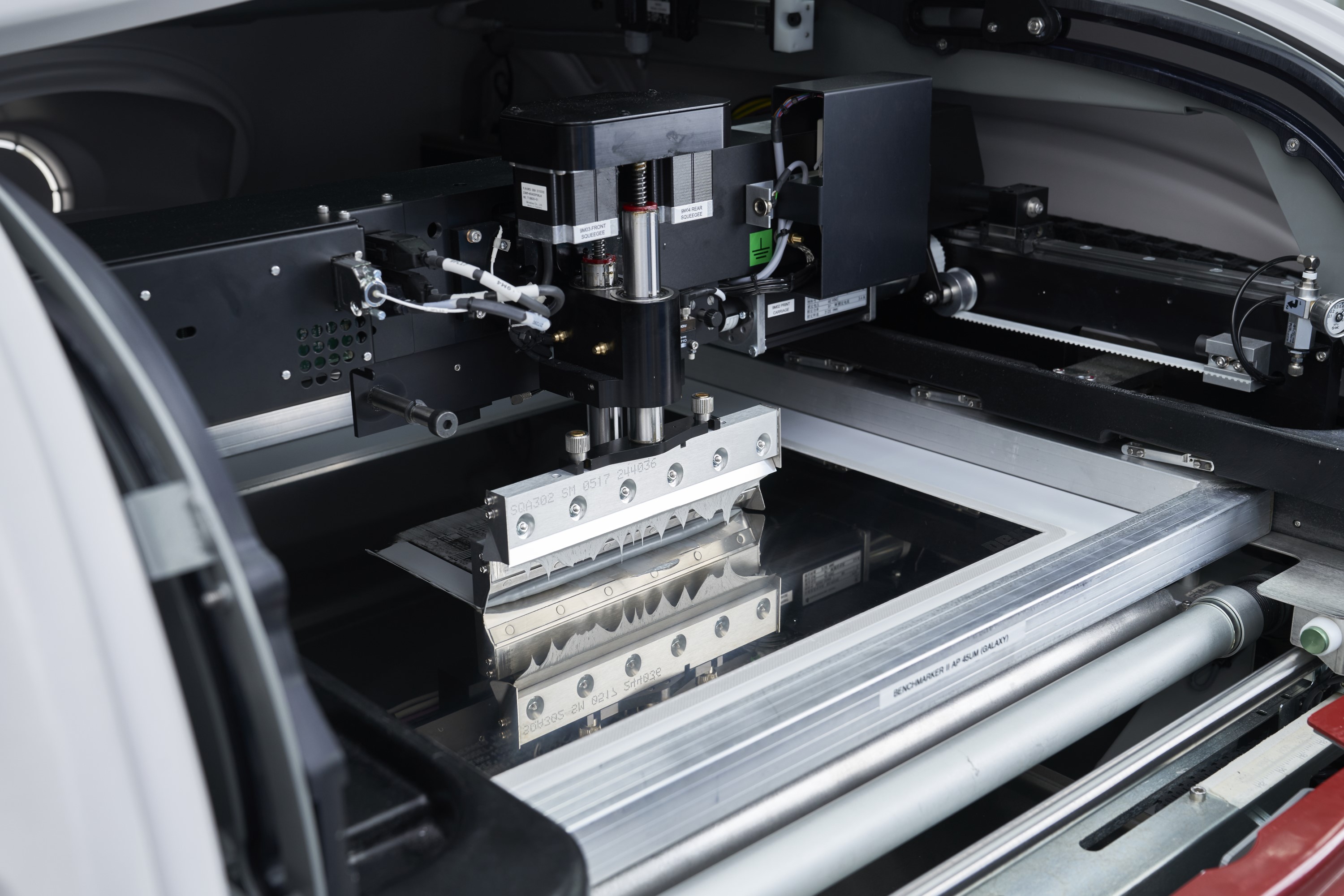

The state-of-the-art application center in Singapore offers comprehensive application services aimed at being a full-fledged advanced packaging hub. With our customers in mind, the application center is equipped with the latest and modern equipment to deliver a quick response in test options and results. In addition to the application center, the climate-controlled cleanroom has a unique ability to match the customers' environmental conditions regardless of region. The cleanrooms’ comprehensive state-of-the-art equipment provides the highest customer support level - due to closer proximity to the customers' production line. Our engineers also work on product development, prototype design, performance testing, and material system qualification for the advanced packaging industries.

Our optimum infrastructure and comprehensive equipment have shortened the product development cycles through our application expertise in matching materials and a better success rate of first-time development. Our experienced engineers in packaging solutions will significantly benefit you and your team to succeed.