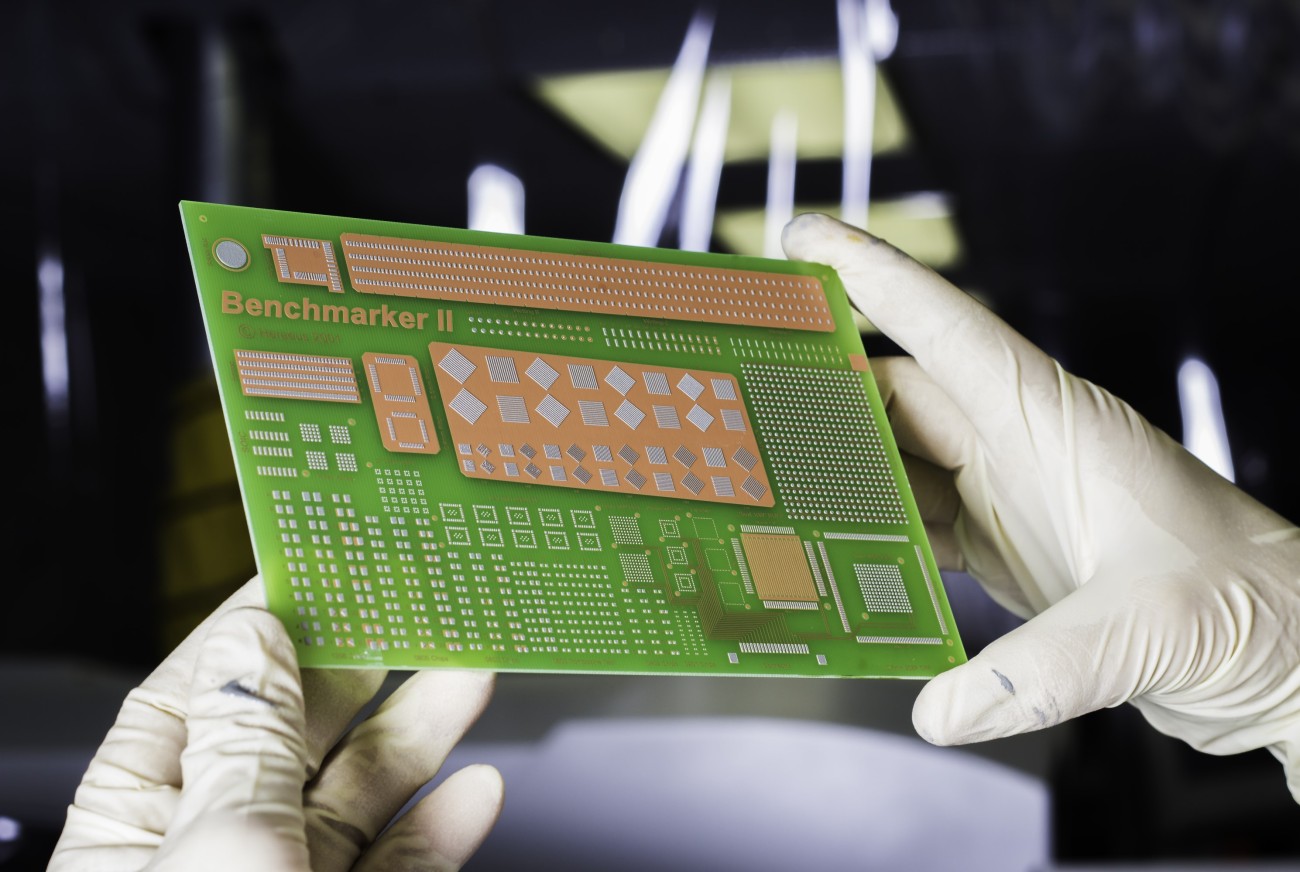

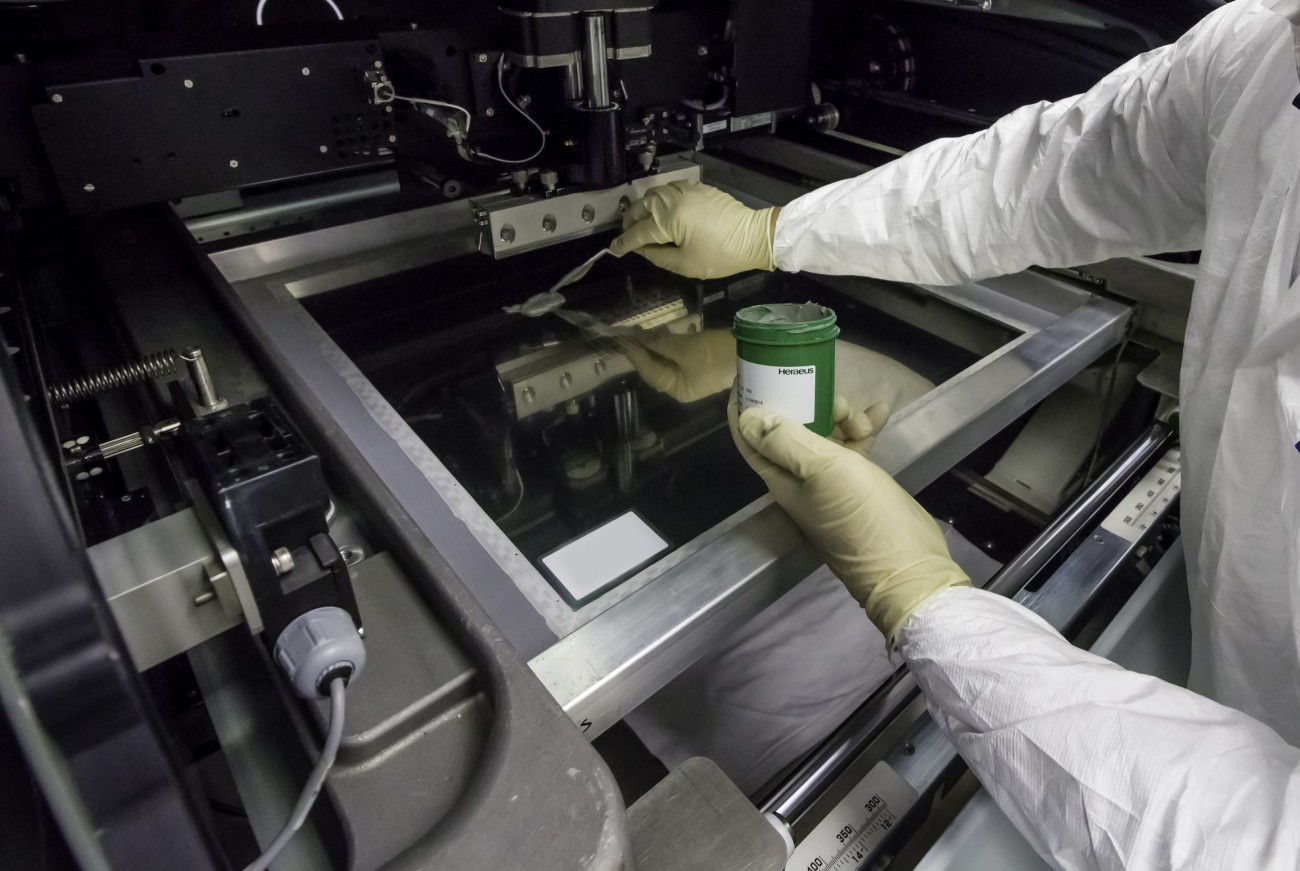

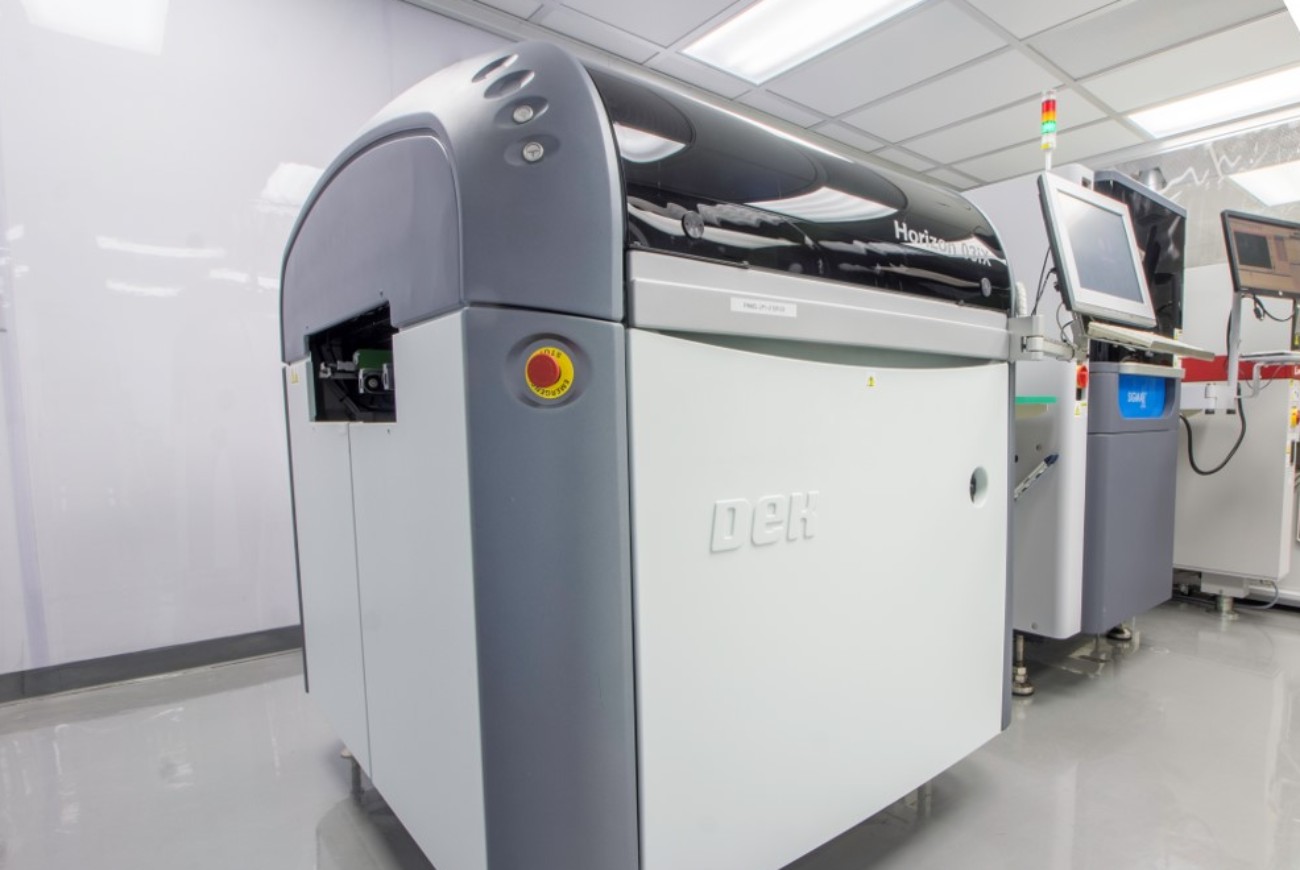

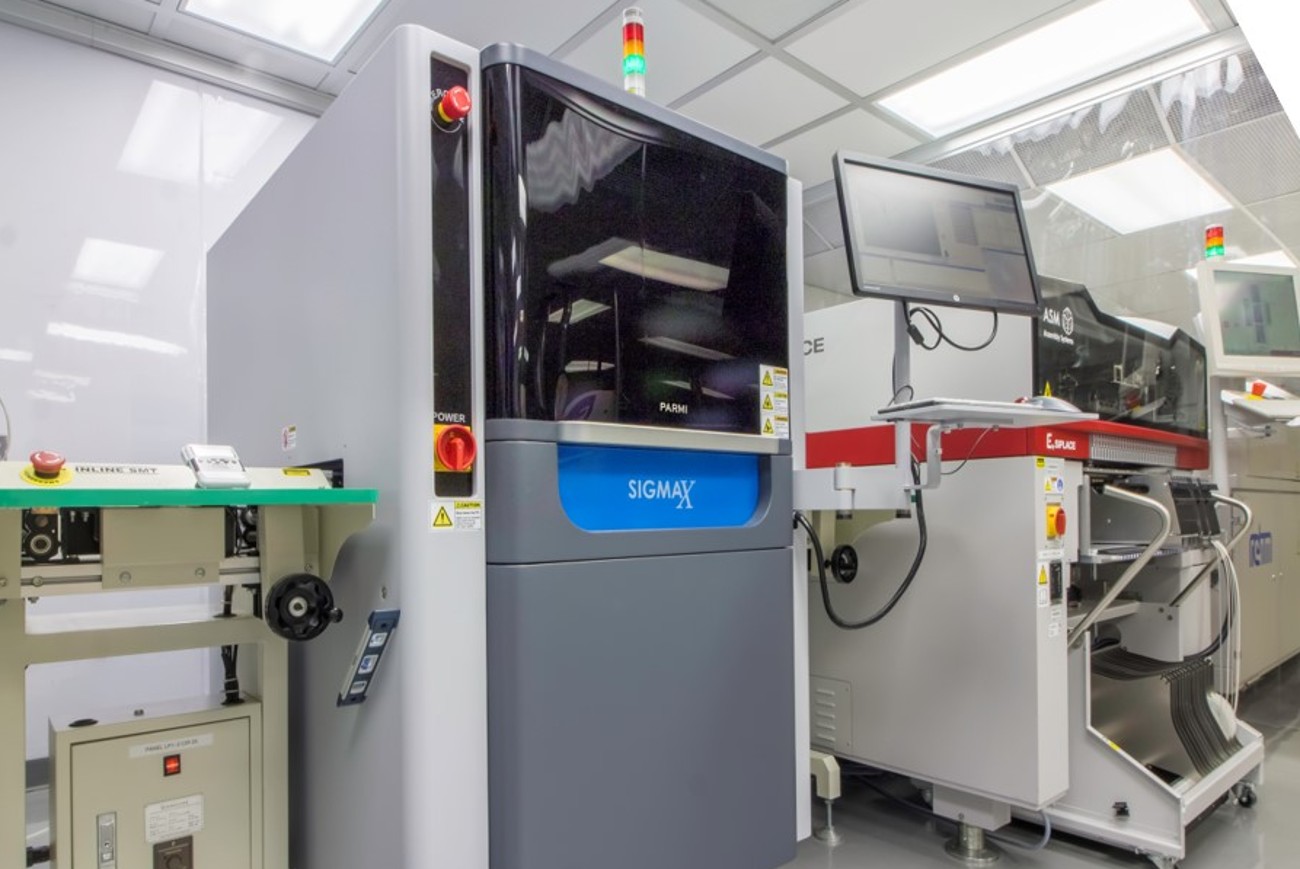

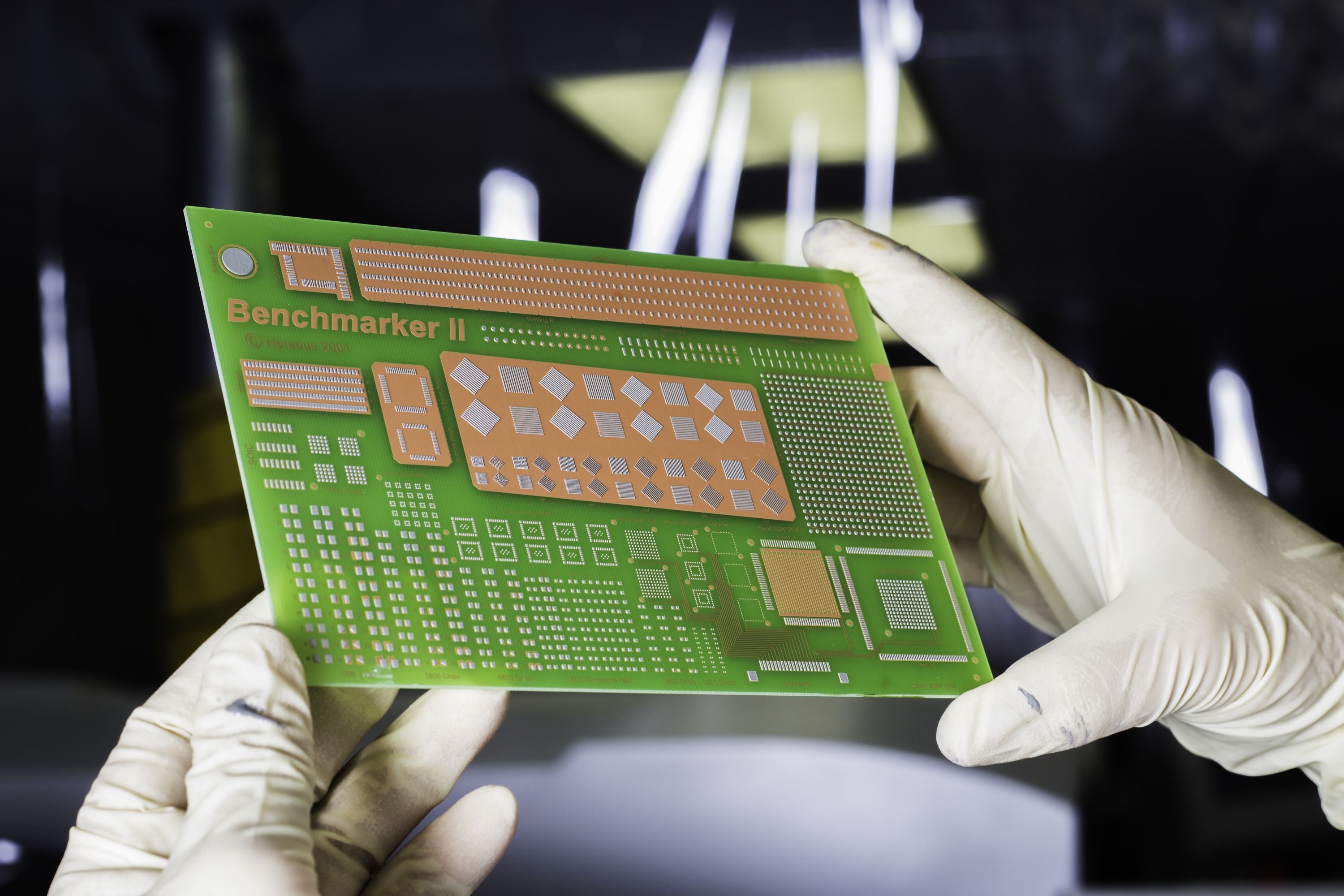

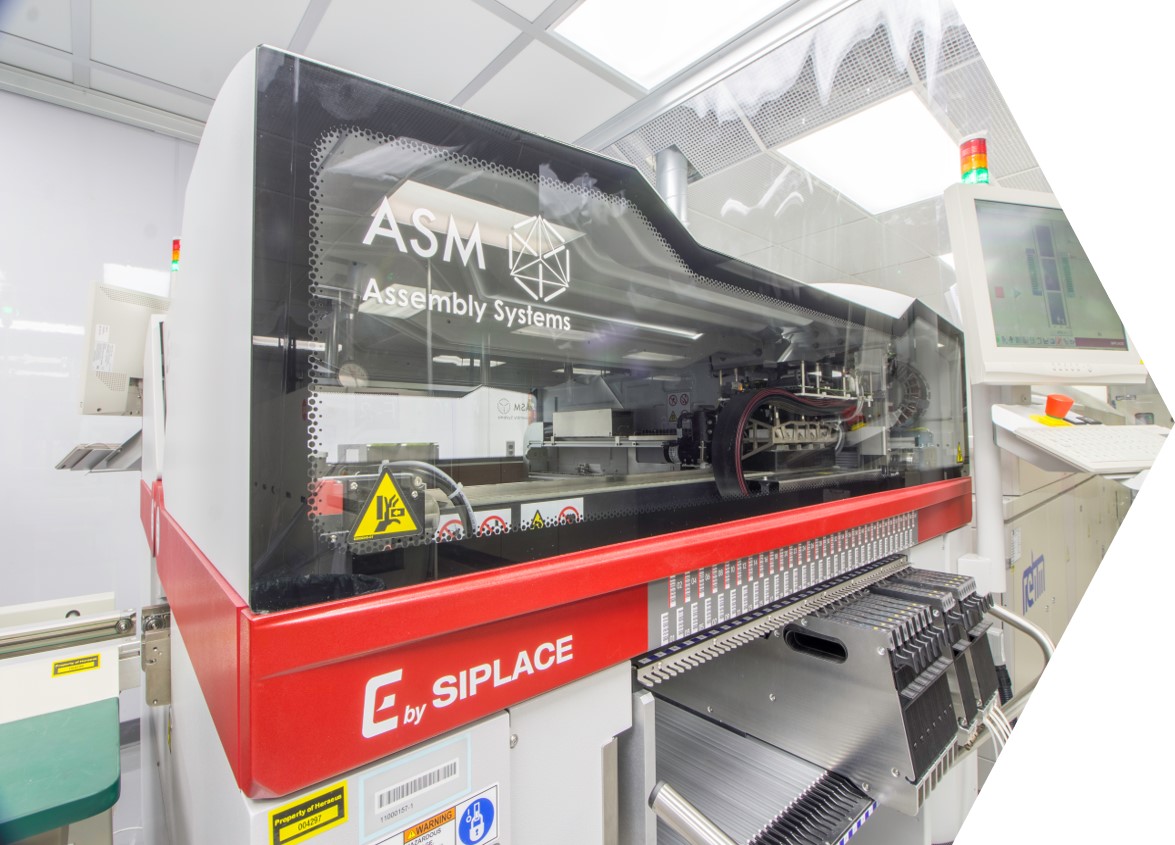

Our state-of-the-art application center in West Conshohocken, PA, offers a wide range of services with advanced SMT to develop customer specific solutions. It includes a complete in-line automated SMT assembly line that customers can utilize to optimize processes, collaborate on product development and conduct trouble-shooting on industry issues.

One of the many highlights of the new lab is its climate-controlled clean room. With the unique ability to match customer environmental conditions regardless of region, Heraeus is able to systematically optimize associated processes and successfully develop products to better match customer requirements. In addition to the clean room, the lab includes a comprehensive array of state-of-the-art equipment to provide the highest level of support

Benefit from a faster developments and market introduction, by working with our engineers in a state-of-the-art laboratory. Our service portfolio together with our experience in packaging solutions contribute to your success.

Your benefits at a glance

- Access to state of the art assembly line

- Local technical experts solving your complex systems and materials challenges

- Future Training Programs: Local SMT product and process training programs at our facility, hands-on and practical for your teams

- Process optimization for improved reliability

- Reduced development risks

- Shortened development cycles and faster time to market

- Higher first-time success rates

- Efficient use of resources in value chain