The SMD (surface mount device) is a standardized electronic package format that supports mounting of electronic components on printed circuit boards (PCBs).

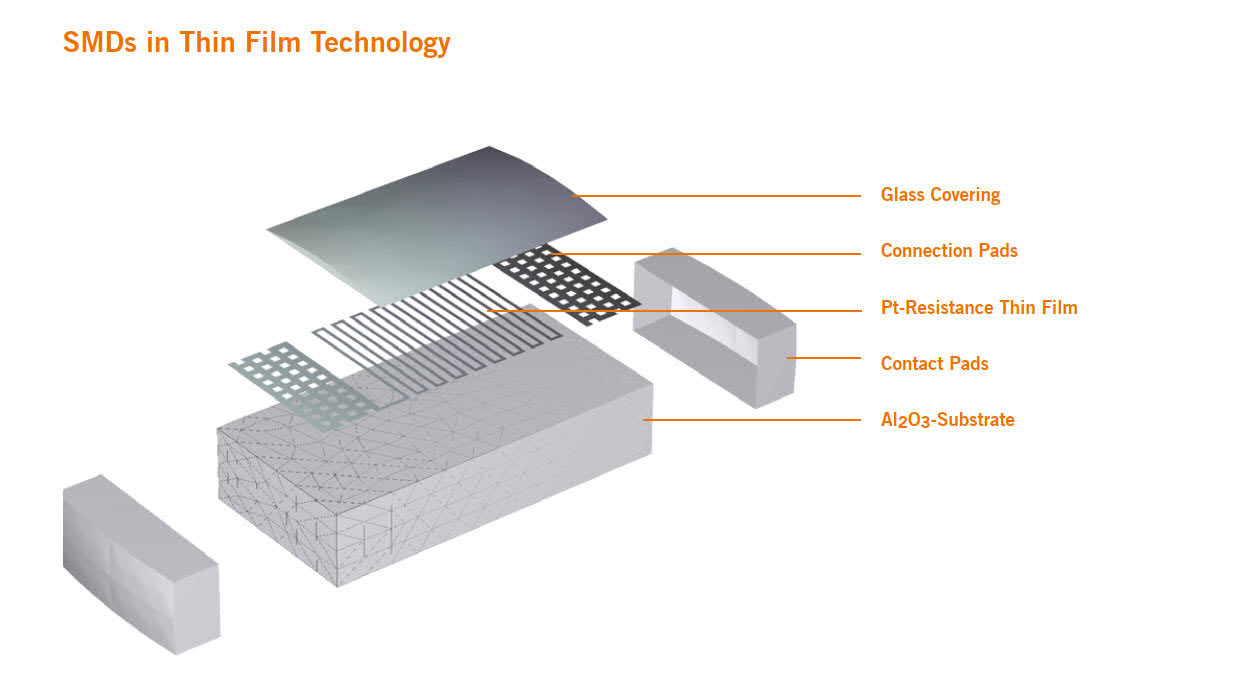

Platinum-RTDs (Resistance Temperature Detector) in standard SMD packages combine the advantages of Pt-based RTDs, such as a linear, standardized signal characteristic according to DIN EN 60751, high accuracy, and long-term stability, with the standardized electronic SMD format for surface mounting. The sensor enables reliable and precise temperature measurements over a wide temperature range, with the additional benefits of competitive cost and automated mounting capability on printed circuit boards.