To fight climate change, governments set ambitious targets to reach “net zero” CO2 emissions. While this is a big challenge for all areas that have been utilizing fossil sources for decades, the energy sector is one of the most pressing with high complexity. New feedstocks need to fulfill the same requirements that has been fulfilled by the fossil sources. It needs to be available at the required scale, storable, transportable and in addition – truly carbon neutral.

In principle, enough green energy is available such as power from the wind and the sun. However, infrastructure needs to be built, to utilize these natural resources to the needed extend.

In both areas, precious metals are involved, for example with

slip rings

for wind power facilities or the

silver paste coatings

for solar power cells.

But generating electricity, even if in sufficient amount, only half the target is achieved. Green electricity sources are fluctuating depending on the weather, the time of year and in day and night. Possibilities are needed to store the energy and to retrieve it later. Also, it needs to be transportable, best by already available decentral infrastructure.

To achieve this, the green electricity is converted into hydrogen by water electrolysis – and then either used directly (by burning or in a fuel cell) or transformed into more sophisticated carriers such as

ammonia

,

LOHC

or

SNG

.

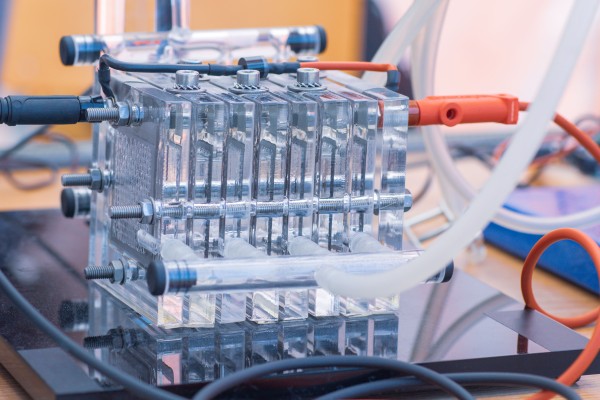

There are several technologies for water electrolysis, however they are not equally suited to the fluctuating energy supply from green electricity sources. The method of choice for green electricity is PEM (Proton Exchange Membrane) Electrolysis, as it works with comparably fast start-up times and needs less space than, e.g. AEL (Alkali Electrolysis), which can be a limiting factor in some settings, e.g. in offshore wind parks. Also it can be operated at lower temperature than e.g. SOEC (Solid Oxide Electrolysis) which is better suited for settings where waste heat out of other processes is available.

Therefore,

PEM Electrolysis

will play a more important role in the futures as this relatively new technology shows interesting potential to provide true carbon neutral for the decarbonization demand. In terms of precious metals, innovations are targeting to taggle the required precious loading per GigaWatt, long term stability, and a sustainable sourcing strategy for the raw materials to make hydrogen ramp-up happen.

Heraeus

low iridium materials

are an important step on that journey, as well as investments in required capacities for the

recycling

of end-of-life materials.