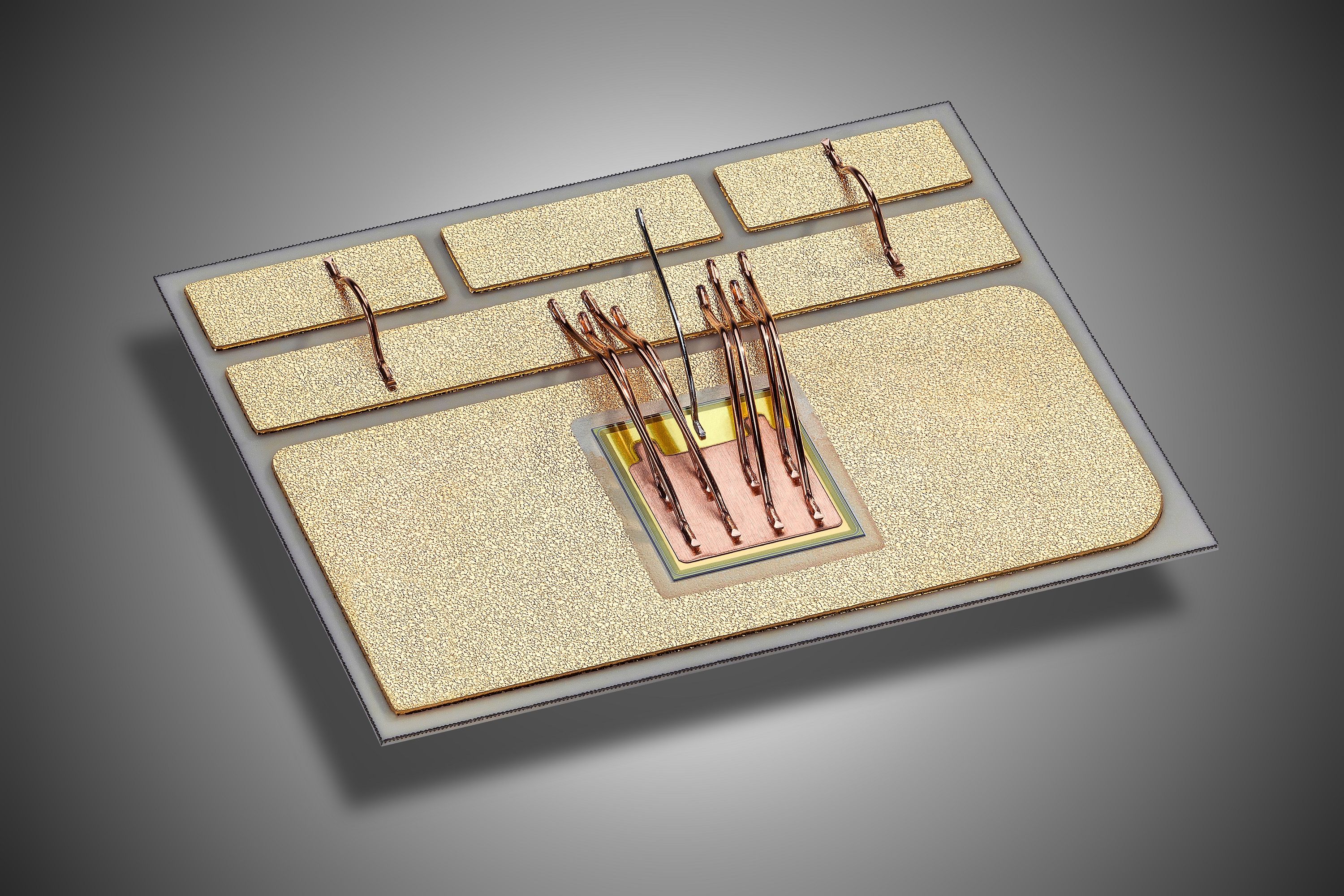

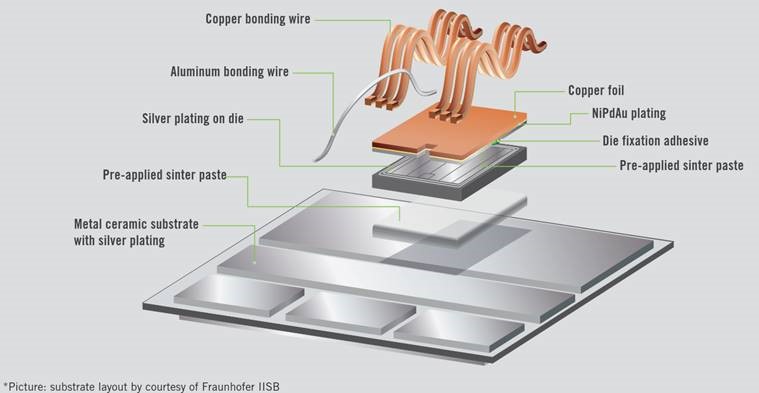

You want to boost lifetime and power density in your power modules? Free yourself from the technical limitations that come with today’s standard die interconnection based on solder paste and aluminum wire bonding.

With the new Heraeus Die Top System – short DTS® – you can achieve a more than 50 times longer lifetime and an over 50 % higher die current capability. DTS furthermore opens the road for junction temperatures of more than 200° Celsius. Thereby, DTS will positively affect your cost per ampere, by significantly decreasing power derating or by reducing the chip size at same ampere.