RTDs in standard SMD packages are designed for automated board mounting in high-volume applications on printed circuit boards where long-time stability, interchangeability combined with cost efficiency are important. The SMD elements are delivered in blister reels or on wafer frame, both offering optimum protection and storage times of up to 6 months - ready for processing with standard “pick and place” technology.

Sinterable and Solderable SMD Sensors – Reliable Protection for Power Electronics

Sinterable Temperature Sensor

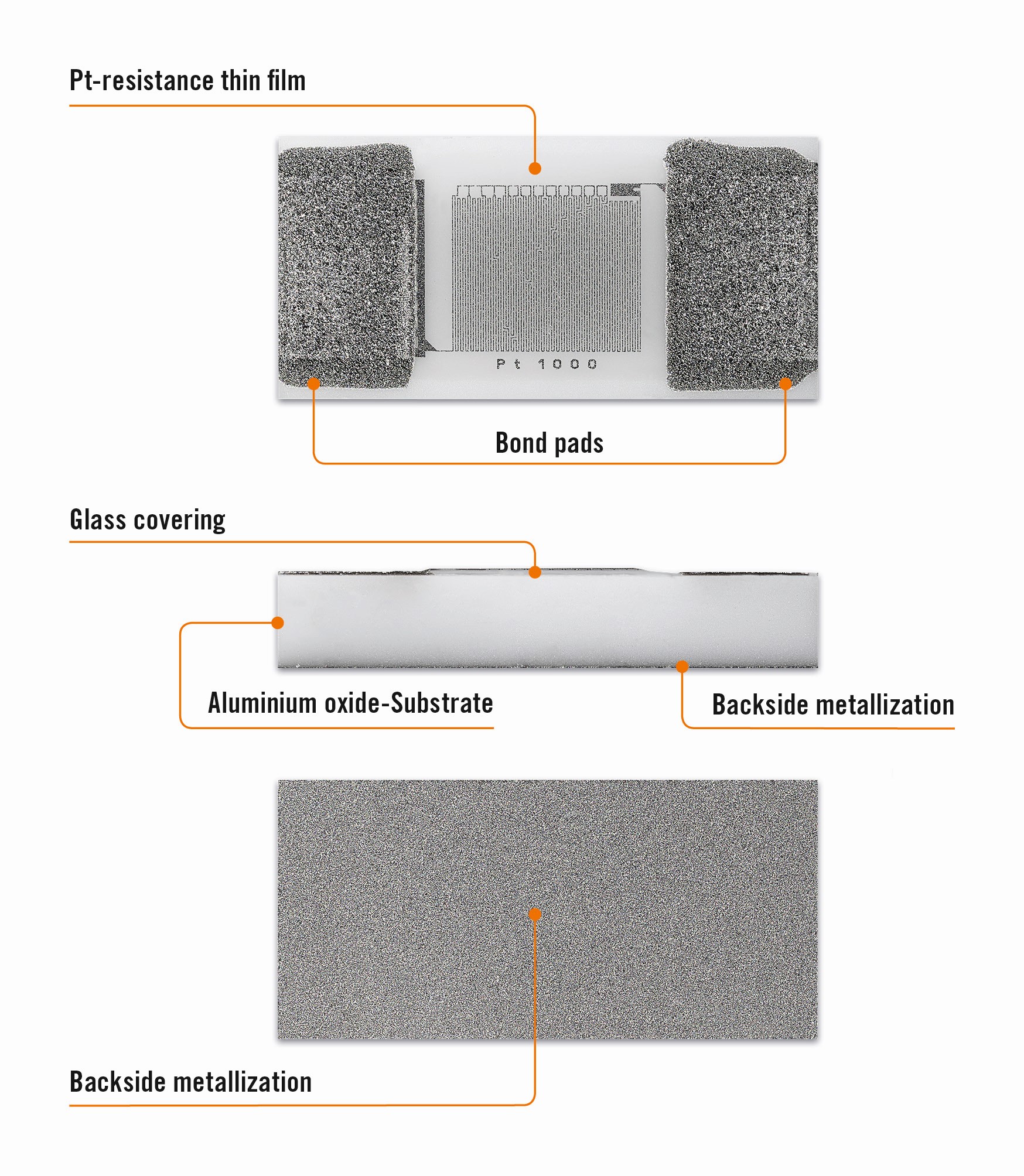

Performance in electric vehicles is mainly determined by the layout of the power electronics. This component should deliver efficient power conversion while being compact. Next generation power electronics based on SiC or GaN technology offer the next efficiency step by operating at higher frequencies and at higher temperatures; operation under these conditions makes reliable connection of the components mandatory – and paves the way for sinter technology. The backside metallization of our SMD-type temperature sensor element is designed for standard silver sintering allowing for a seamless integration in an existing production environment. The design of the sensor element allows for a potential free positioning next to the heat source without the need for additional insulation architectures on the substrate between the die and the sensor. Reaction times becomes faster and more accurate. The topside metallization is developed for state-of-the-art Al-thick wire bonding.

Solderable Temperature Sensor

Soldering is a standard method for pick-and-place assembly of power electronic boards. The boards are key components for energy management in wind and solar parks, trains, elevators, and many other applications. The solderable SMD allows to upgrade to the next level without modifying your production process: our solderable SMD-type temperature sensor provides design freedom, improves accuracy, and allows for the next generation power dies.

Our Innovation – Your Advantage

- Assembly by sintering or soldering processing

- Location close to the heat source for precise measurements and fast response times

- Potential free position direct to the heat source / die, electrical insulation from die by design

- Top side connection with standard bonding wires (e.g., Heraeus Al H11 Ø 300µm)

- Long- term stable, high precision temperature sensing with standardized characteristics by Pt-technology

- Application temperature window exceeding 200 °C depending on joining technology

Technical Data

SMD 1206 SC sensor elements have the following configuration:

- Temperature coefficient (TCR): 3850 ppm/K

- Temperature range from -50 °C to over +200 °C

- Pt-based characteristics of temperature sensing

- RoHS compliant