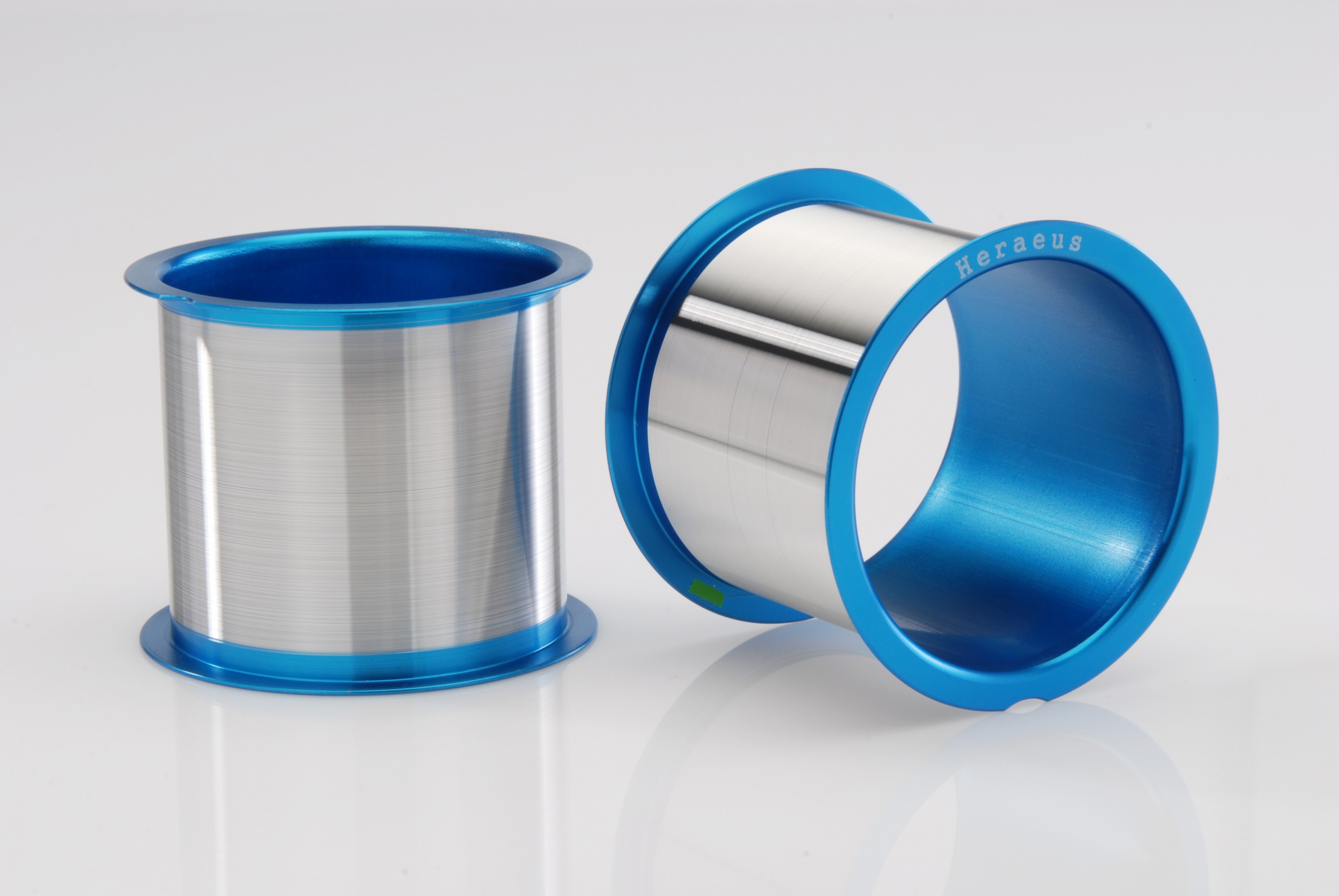

The small-diameter aluminum wedge bonding wire available from Heraeus is made of high-quality AlSi alloy and goes by the brand name of AlSi. Its principal applications are in motor vehicles, consumer electronics, and computers.

In contrast to heavy aluminum wire, which is used to carry power, fine aluminum bonding wire is dedicated for signal transmission and processing. It is commonly used for Chip-On-Board (COB) applications. AlSi aluminum-alloy wire include compatibility with the aluminum on IC bonding pads, especially in fine-pitch applications. It can be easily and cost-effectively bonded at room temperature and is thus ideal for forming high-integrity bonds and preventing damage to sensitive devices. The electrical and thermal conductivity properties of AlSi are also excellent for a wide range of uses.

Compared to other suppliers, aluminum bonding wires belong to our strategic core business. We are capable to match it to our comprehensive assembly material program and therefore reach better reliability, performance, and workability.

This helps you to speed up your development and optimization processes, and bring your products to market faster.