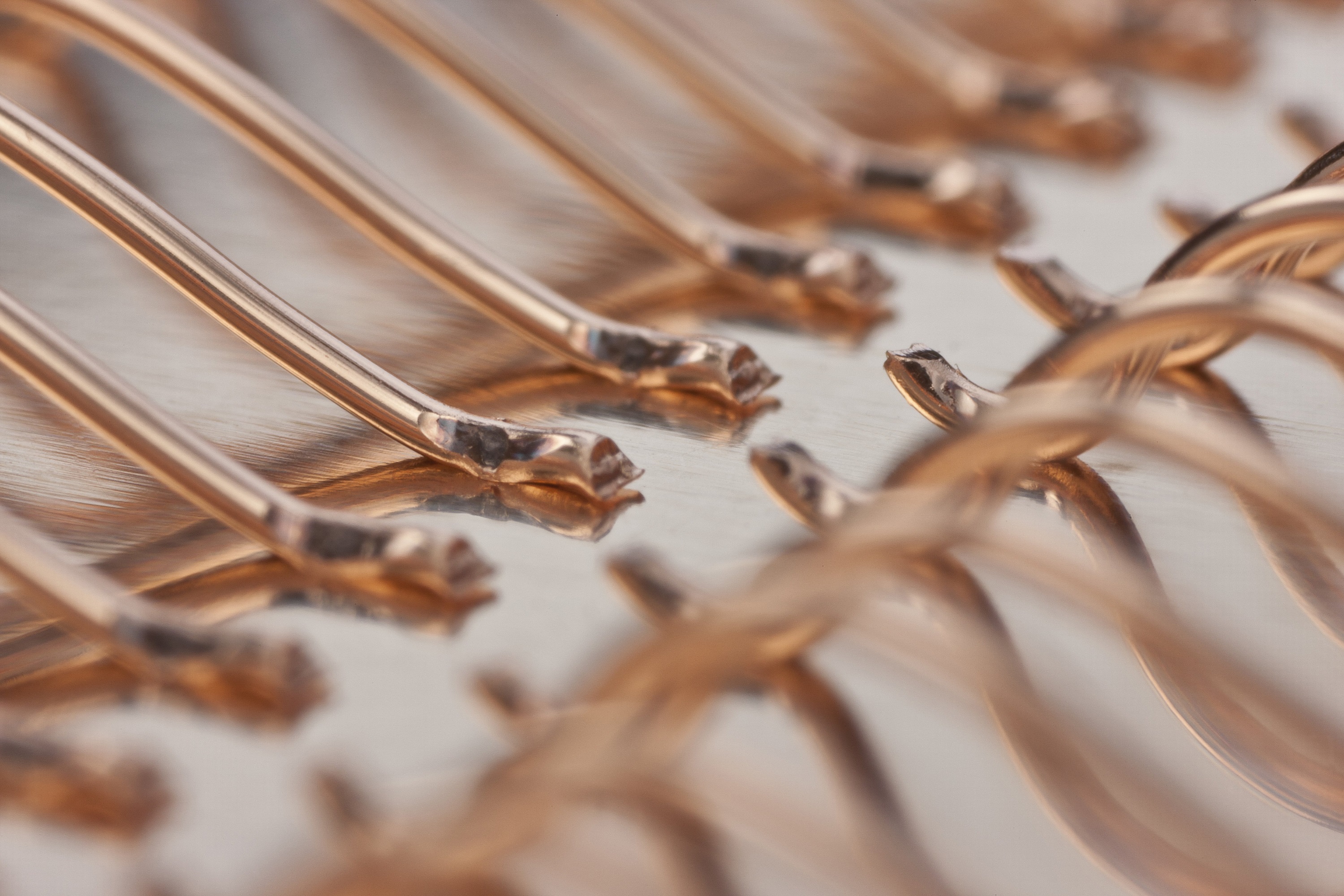

Copper as an interconnect material provides excellent electrical conductivity and fusing current values. That enables the use of thinner wires compared to aluminum wire connecting, resulting in better heat dissipation. In addition, copper is a mechanically stable metal, resulting in stronger wire connections and high loop stability.

PowerCu Soft Wires and Ribbons exhibit outstanding long-term reliability and result in highly robust bonds able to resist high temperatures and mechanical stresses. Wires and Ribbons of the PowerCu Soft family are ideal for helping you solve the challenges posed by thermal management, the need for high robustness, miniaturization and weight reduction, as well as increased reliability. This includes power management in high-voltage modules and systems, even at high energy densities and temperatures.

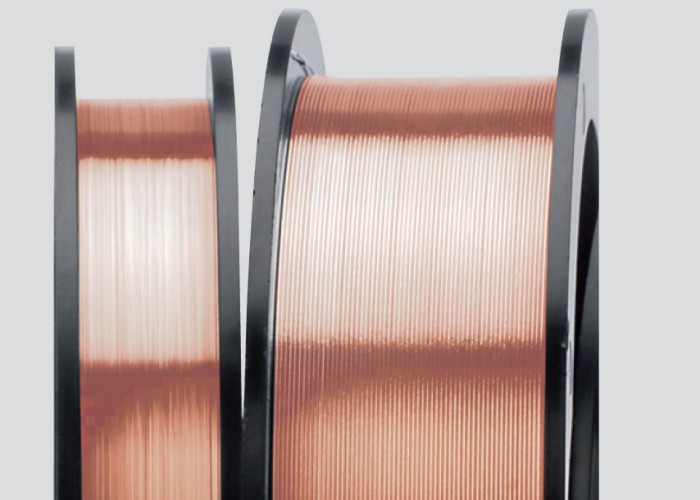

We are unique in focusing on thick bonding wires as part of our core business, while in parallel offering solder and sinter pastes, substrate materials, and other power electronics products. We supply these products in forms that simplify and streamline your own processes by enabling lean, cost-effective production with standardized methods.