Electronic devices need to perform more in a smaller space with every new generation. Due to this trend, components become smaller and smaller, structures finer and finer. At the same time, the cost pressure leads to the development of cost-effective solutions, such as copper, and the demand for higher reliability raises.

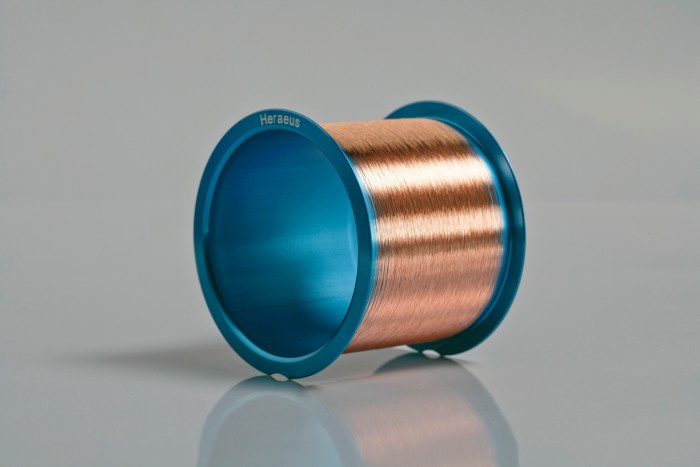

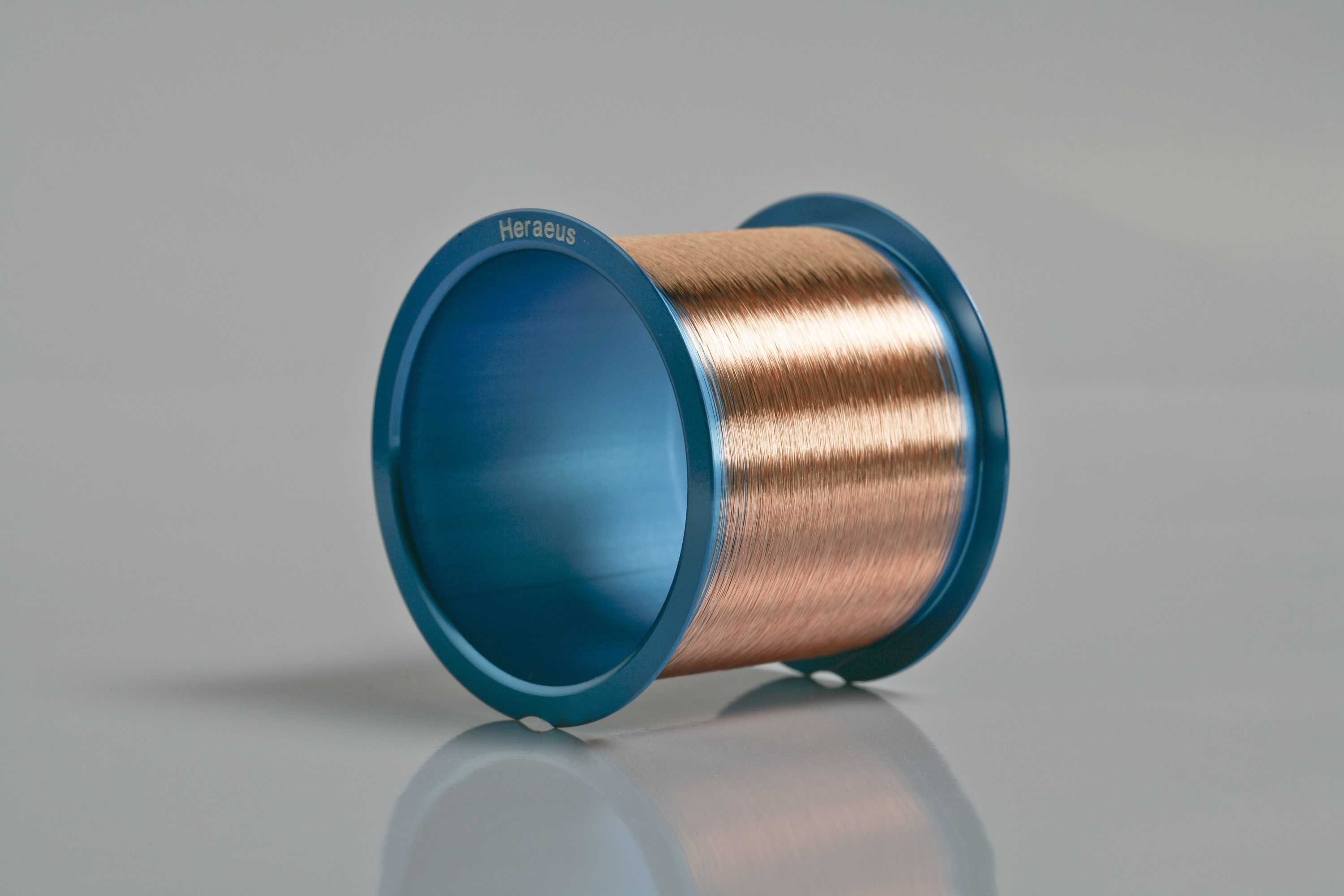

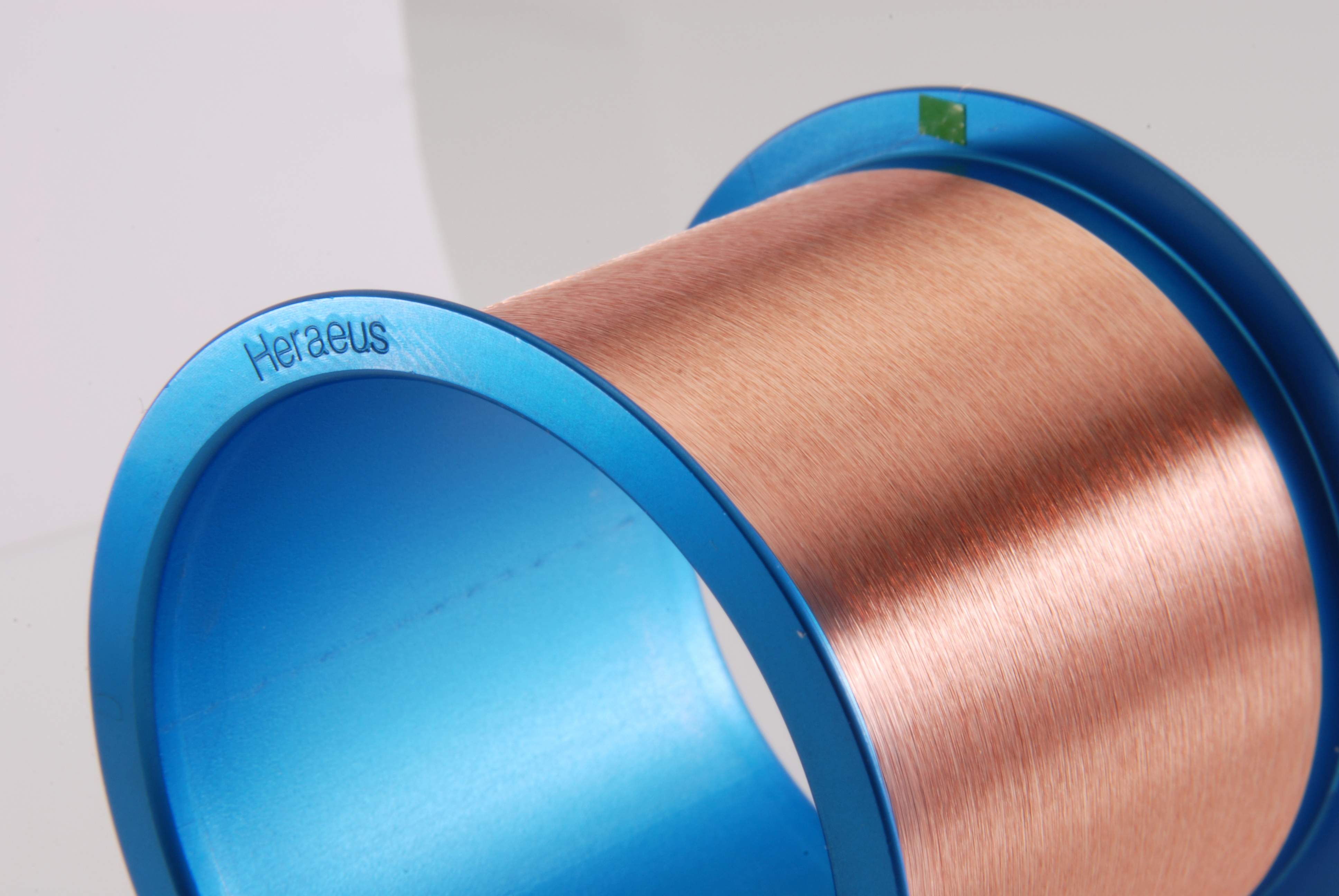

Heraeus copper bonding wires are in many cases a good alternative to expensive gold based solutions. With their ultra-fine diameters (0.6 mils or 15 µm) they are suitable for very small structures with ultra-fine pitch. By adding alloy elements to the bare Cu wire or using CuPd / AFPC core cu wire, our bonding wires show advanced reliability and very good bondability. In many applications copper wire bonding can even provide better performance and reliability than gold wire bonding.

Copper bonding wires are excellent for bonding in a ball / wedge process when using a reduced protective gas atmosphere. Processing is also possible in a wedge / wedge bonding process.

Find your ideal solution from our wide range of products (PdFlash, PdSoft, PdPro, DHF & iCu and MaxSoft). Heraeus specialists with years of experience support you with their technical expertise and application know-how. On-site, they help you with the evaluation and qualification, especially on complex issues and configurations. Tests in our application and technology center enable us to test your adaptations directly in the application. Save time and money with Heraeus as a qualified partner and accelerate your developing process.

Please click

here

to view the full list of Heraeus trademarks.