Power electronic modules use a ceramic substrate such as Al2O3 or ZTA (Zirconia Toughened Alumina) serving as an insulating layer, and copper connections to ensure the electrical conductivity at high temperatures.

For improved mechanical robustness, to achieve higher reliability, Condura®.extra (Zirconia-toughened DCB-Al2O3 substrates) is the material of choice. Condura®.extra is based of aluminum oxide material in which up to 30 % of ZrO2 are deposited in the ceramic matrix. It’s bending strength is higher than 500 MPa while aluminum oxide ceramics has about 400 MPa.

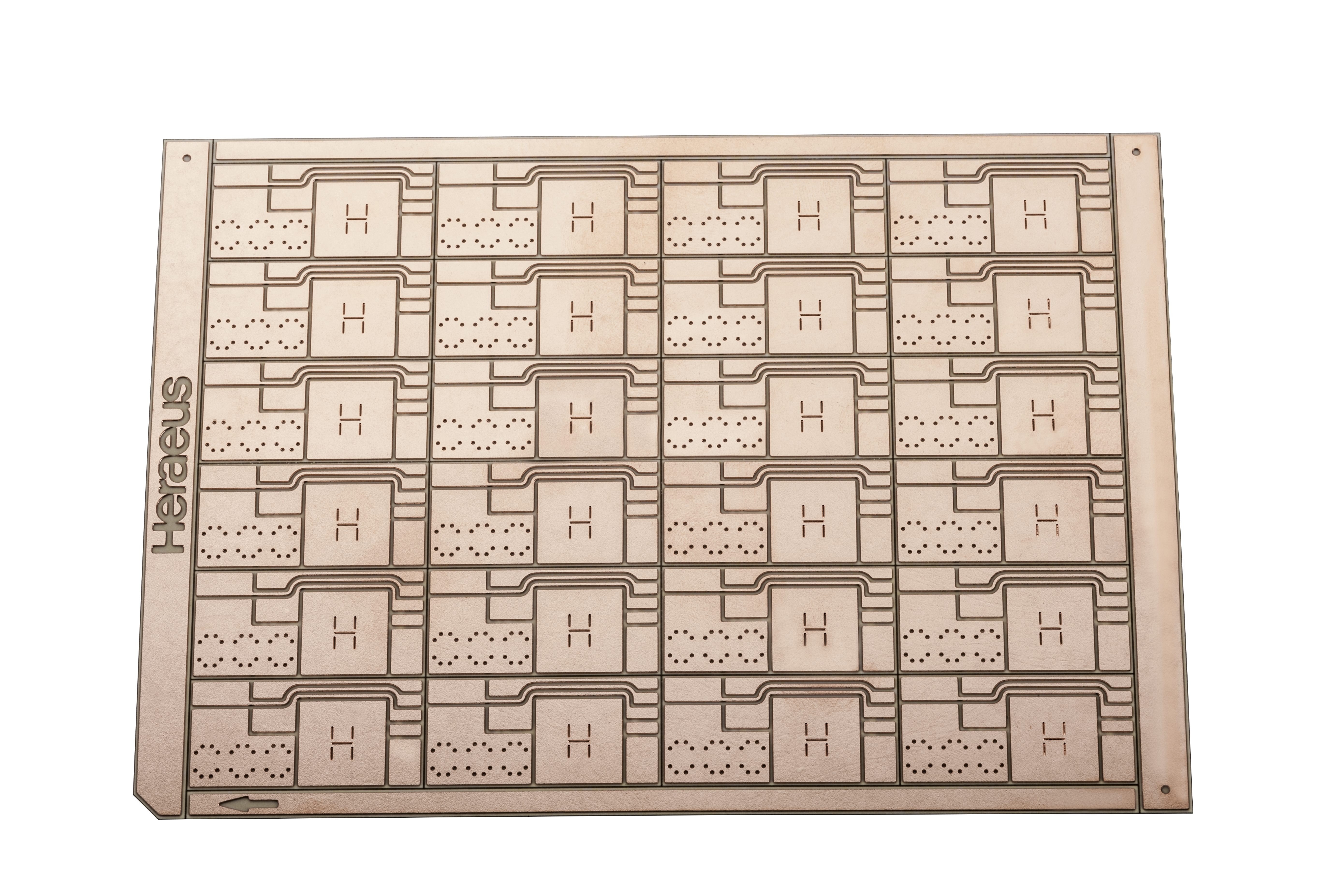

Heraeus as experts of long standing offers you support in the development stages, and in doing so, help to save you both time and money.