Composite materials are different based on their purpose: short-fibre reinforced thermosetting plastics for large car body parts, long-fibre reinforced thermoplastics for high-strength structural components, woven rovings for wind energy plants or filament windings for sleeves and pressure cylinders. They all have in common that they are to be produced in the most cost-efficient way.

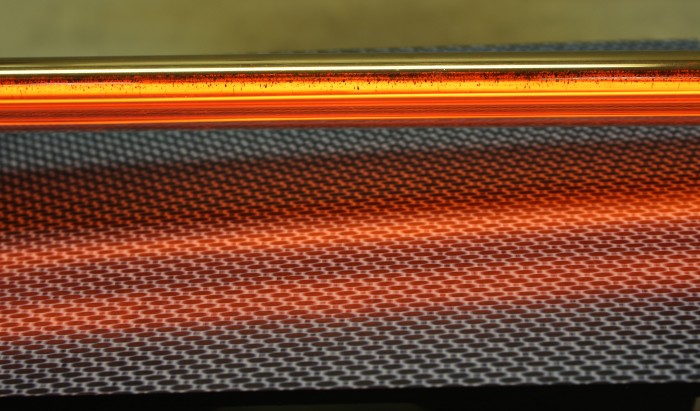

To fabricate these modern components, infrared heat or UV radiation are used because they quickly and homogeneously heat or cure them and in this way shorten process times.

New: humm3® - Intelligent heat for Automated Fibre Placement