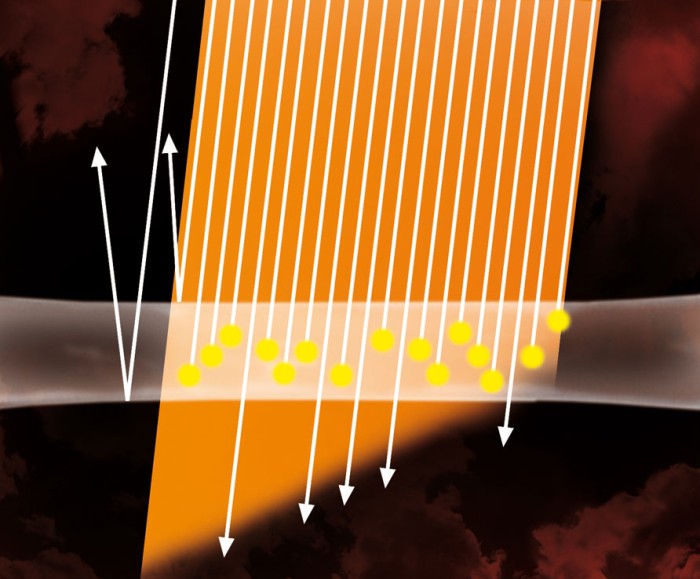

Infrared heat technology works by transmitting electromagnetic waves which generate heat within the product.

- Heating requires no contact

- High heat transmission capacity

- Fast transfer with high power

- No energy wasted to a transmission medium

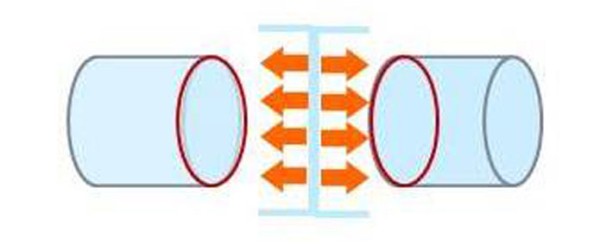

Infrared radiation adjusted to product and process

Part of the electromagnetic radiation is absorbed in the material, another portion is reflected and the rest penetrates the materials. Only the absorbed portion contributes to heating. Each material has its own absorption spectrum, the range in which the electromagnetic radiation is best absorbed.

When the emission spectrum of an infrared emitter is optimally adjusted to a material's absorption spectrum, the material is heated much faster and much more efficiently.

We offer tests, trainings and tech days in our modern application centers!