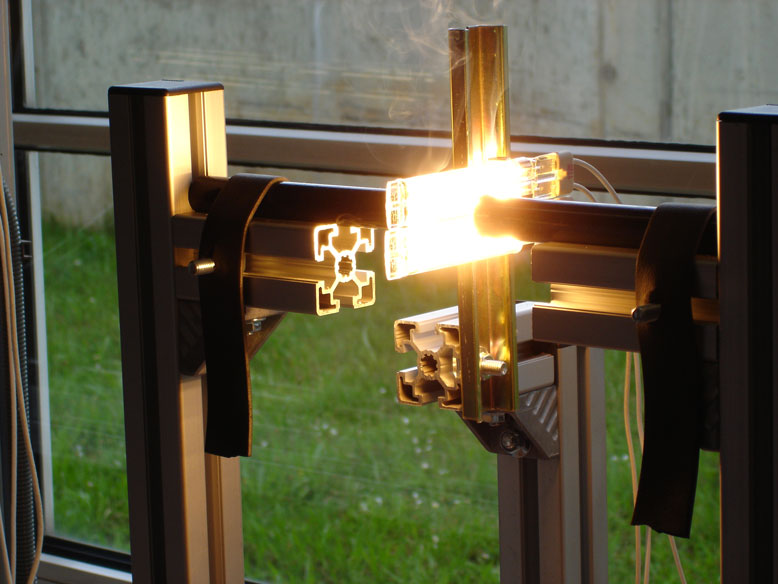

The heating process in plastics processing is much quicker for darker materials. The reason behind this is that black plastic absorbs infrared radiation better than white or transparent materials.

In experiments with black and transparent plastics surprising time differences were detected when joining two plastic shells together.

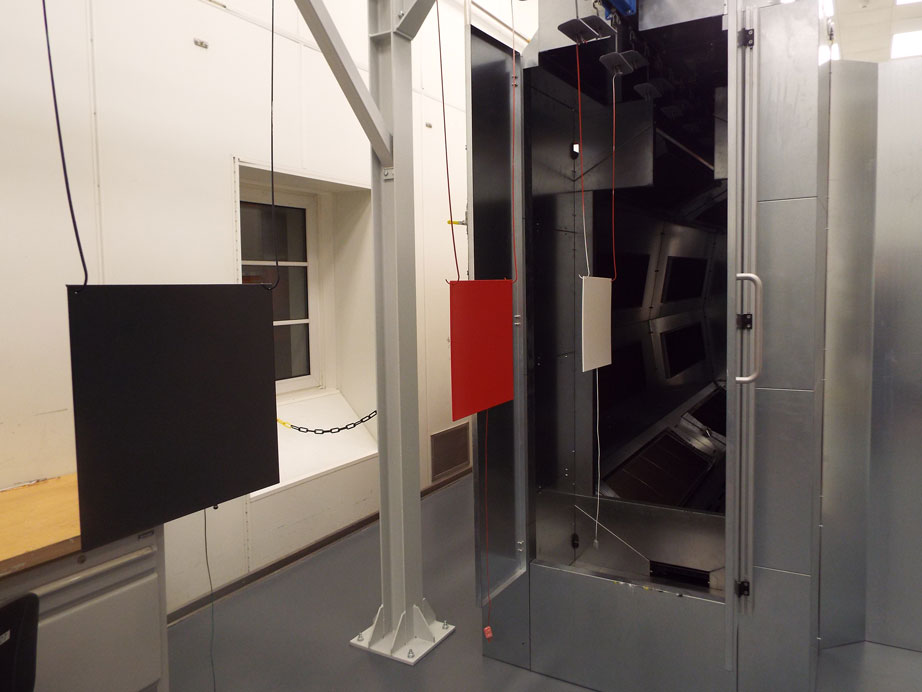

Experiments show that when two half shells made of polyamide are joined together to form a hollow body, heating times vary considerably depending on the color of the plastic. At the same temperature, the shells only need 12 seconds of heat if they are made of black material; but they take up to 40 seconds if the plastic is white or transparent.