Rapid Thermal Processing refers to manufacturing processes:

- which heat materials to high temperatures

- on a timescale of seconds or even milliseconds

Such rapid heating rates are often attained by high intensity lamps or lasers.

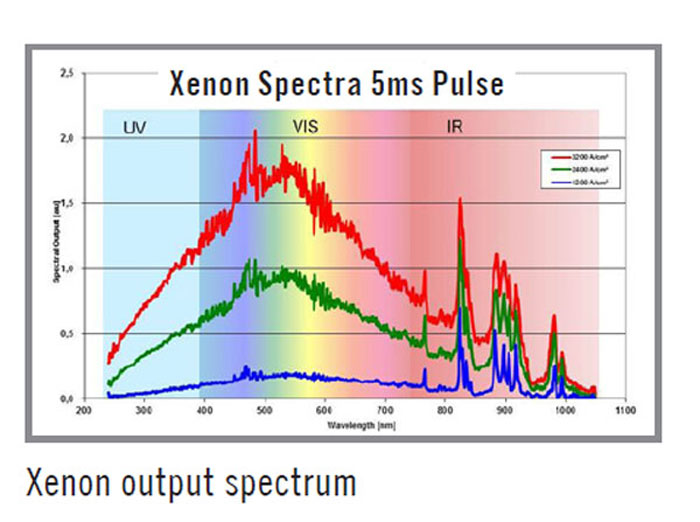

Xenon Flash lamps can serve a wide range of processes where high energy output is needed across the broadband spectrum, from 160nm – 1000nm. The light output can be used as an energy source for the curing, heating or annealing of surfaces or coatings. Flash lamps can be operated as Continuous or Pulsed light sources, and by altering the pulse shape, duration or current density can maximise output for your desired wavelength range, and achieve optimal process results.

A unique industry combination of flash lamp technology, system design, power delivery expertise and energy density homogeneity prediction, puts Noblelight Arc and Flash in an ideal position to offer you the most efficient customized solution for your Rapid Thermal Processing requirements.