Infrared radiation transfers heat directly and at high efficiency. Infrared heating technology means heat only where it is needed, at the optimal wavelength for the material and in line with the process.

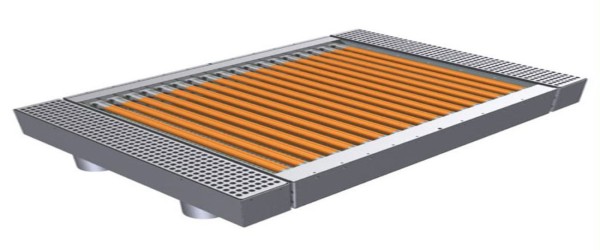

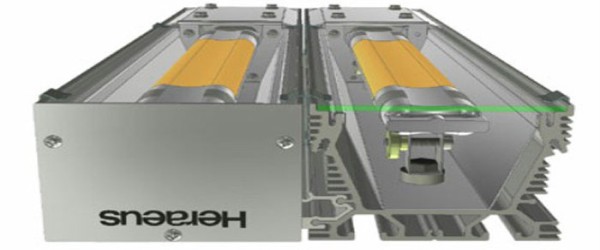

Different wavelengths are more suitable or less suitable for a particular process according to the absorption properties of the material and the practical requirements of the production process. Noblelight is a specialist in custom-built infrared heaters. We assist in the selection of the optimal type of heater for each application. Noblelight helps develop solutions that are matched precisely to the requirements of the user. The development of heaters is centered on the needs of customers and the latest state-of-the-art technologies. Noblelight infrared modules comprise one or more infrared lamps mounted in a suitable housing and usually wired into a terminal box mounted on the back of the unit. System solutions include modules and a control panel designed to meet the requirements of the individual process.