Some of the primary benefits of UV LED curing include reduced maintenance, lower operating costs, and less downtime compared to medium pressure arc lamp UV curing systems. UV LED curing systems use less energy, have significantly longer useful lifetimes, use fewer consumable parts, transmit less heat to the substrate, and can be turned on/off instantly and even dimmed to meet different process requirements. (Learn more about

improving converting UV curing processes with UV LED curing

.)The long wavelength output of today’s UV LED curing systems, 365, 385 and 395 nm, are an excellent fit for existing iron additive curing processes such as laminating adhesives. In spite of the opportunity for

significant improvements in production rates

, some process design engineers may be reluctant to embrace UV LED curing due to its rapid advancements, fearing their equipment and UV LED curing process will soon be outdated and require high costs to upgrade.

How to “Future Proof” UV LED Curing Processes

UV LED curing offers many benefits for manufacturing production processes -- benefits that improve production rates. However, investing now in UV LED curing equipment can seem risky given how rapidly the technology is advancing. In this article we’ll discuss UV LED curing benefits, the technology advancement trends, and steps you can take to minimize early adopter risks.

UV LED curing benefits

Rapid technology advancements

UV LED curing, in commercial use since the mid 2000’s, is advancing rapidly. The UV energy output, or peak irradiance in W/cm2, for air-cooled systems increased from about 1.5 to 11 from 2008 to 2014. Today it is common to find air cooled UV LED curing systems with peak irradiance of 14 W/cm2 and even 16 W/cm2. These advances are due to the historically rapid advancement of UV LED chip technology which has seen 10 – 20% increases in efficiency every 9 – 12 months.

And even more important to end users, UV LED system manufacturers have made significant advances in cooling techniques and optics, enabling tighter packaging of LED chips into arrays and significantly improved optical control resulting in higher UV energy onto the substrate.

As UV LED energy output increases, additional curing applications, such as converting processes which require faster line speeds, become feasible. According to research firm Yolé Développpement, UV LED curing began taking off dramatically in 2012 as shown in the graph below, and is forecast to see 23% growth through 2021. More than 55 manufacturers had entered the UV LED market as of 2014, a clear indication of the technology’s continuing commercial adoption. And with more widespread adoption and increased volume, prices have decreased significantly, dropping about five-fold over the last decade.

So clearly, process development and design engineers face the challenge of knowing when is the right time to begin adopting UV LED curing for their converting and laminating processes – too late and you’re seen as a laggard, but too early and your equipment and process might be costly and time consuming to upgrade as the technology improves.

How to future proof UV LED curing process

One of the best ways to ensure your UV LED curing equipment and your converting production process remains state-of-the-art is to “future proof” it. That is, look for equipment which is easily upgradeable and flexible in order to adapt to both the advances in technology and your changing process needs.

Upgradeable to latest UV LED curing technology

Some UV LED curing system manufacturers build custom systems or systems for the most common line widths, while others use a modular approach. Generally speaking, a custom system or systems for specific widths may be more costly to upgrade to the latest UV LED chip technology, both in terms of cost and downtime, because you’ll need to purchase an entirely new curing unit. Look for a system where it is possible to replace only the UV LED array while keeping everything else, i.e. the emission window, housing, cooling fans, power/controls, and mounting system.

A modular UV LED curing system is one where the UV LED array(s) can be easily removed and replaced, like a toner cartridge in a copy machine, without having to replace other components. For example, users of Semray UV LED curing systems can upgrade the UV LED array to the latest technology with no need to replace cooling, power connections, or other components.

Flexible for changing process needs

In addition to being upgradeable to the latest technology, a UV LED curing system needs to be flexible for future changes in process needs. So being able to change UV processing variables such as:

- wavelengths

- curing width

- level of UV energy output

- working distance

enables greater process flexibility for future needs.

Wavelength and width

Changing wavelengths between the available UV LED arrays, 365, 385, and 395 nm, is easy with a modular system since you can swap out the LED array to a different wavelength.

Some UV LED curing systems enable individual on/off control of sections of the UV LED system spanning a line. This makes it easy to change cure width to match the production width needed and saves energy costs while increasing UV LED equipment useful life.

Semray does this using on/off control in 25mm widths.

Changing energy output and working distances

Most UV LED curing systems vary the level of UV energy output using dimming controls. Changing the energy output is useful for curing different chemistries and/or for products that run at different line speeds. For example, Semray UV LED curing systems can be dimmed from 30 to 100% in 1% steps.

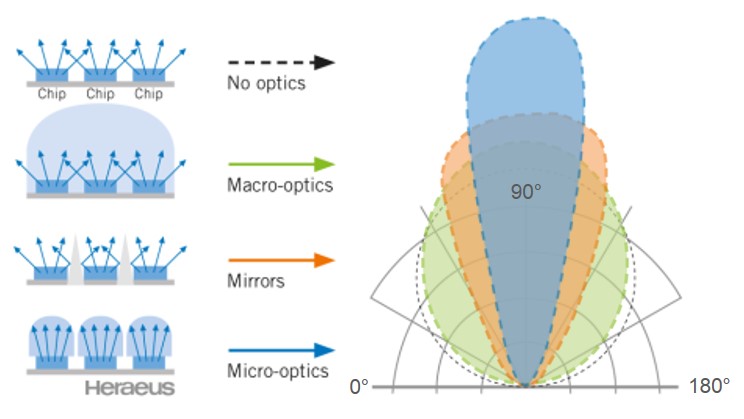

With some UV LED curing systems changing working distances can be problematic because the energy from the LED arrays is emitted at high angles from the emission window. The result is that as the working distance increases, the UV energy reaching the substrate decreases significantly. Look for systems with enhanced optical control to more efficiently focus the UV energy down onto the substrate.

Semray UV LED curing systems use micro-optics internal to the units to capture stray energy and focus it down at 60 degrees instead of the typical 120 degrees from the emission window. The result is much more flexibility to increase working distances to 20mm or even 30mm without significantly reducing UV energy density on the substrate.

Upgradeability and flexibility enable early adoption without risks

UV LED curing has proven its reliability and adaptability in many commercial processes. And with increasingly more powerful LED chip technology every year, we’re now seeing research and development teams at both chemistry formulators and end users commercializing UV LED curing for their converting and laminating processes, even for high speed, wide web lines. Choosing UV LED curing equipment now which is easily upgradeable and flexible will ensure adaptable processes using state-of-the-art technology – a winning combination for future success.

Still have questions? Check out

FAQs: Developing UV LED Curing Processes for Converting Applications

Process Design Comparison Chart: Traditional UV versus UV LED Curing for Converting Applications