A fire may occur in commercial kitchens especially where greases deposit, e.g. in extractor hoods and exhaust air ducts. In such places, even a spark is enough to ignite the old grease.

Hence, even a small fire may rapidly spread and grow large if they are cleaned improperly or too rarely. Still, the use of fat and high temperatures cannot easily be avoided in most kitchens.

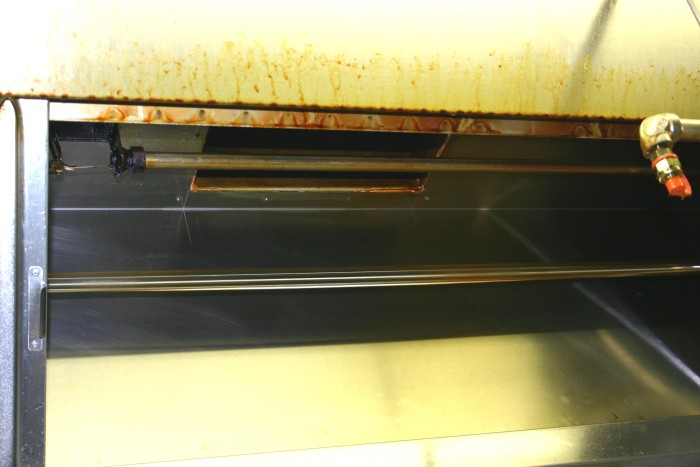

The consequences are major fire hazards and high costs for cleaning the kitchen and the hoods.

UV light destroys the bonds between the odour and fat molecules and breaks them into fragments. This prevents the deposition of grease in the hoods. And it reduces cleaning costs and avoids frequent repairing, e.g. of the fan.

Moreover, the exhaust air discharged into the environment is almost free from grease and odours. This pleases neighbours because objectionable odours are also neutralised. The UV technology allows compliance with regulatory requirements, such as VDI 2052 and DIN 16282.