- Rapid heat/cool with no residual lamp heat – ideal for dynamic heating of dry fibre and thermoplastics composite materials

- Enhanced safety – humm3® is a safe, broadband emitter that doesn’t require a class 4 laser enclosure or the associated safety management burden

- Artificial Optical Radiation (AOR) exposure is measured relative to Exposure Limit Values (ELV), and is the result of what is emitted, the distance of the operator relative to the source and the exposure time. It can be controlled by cell layout, filters, screening, working protocols and PPE

- Option for wide heated width resulting in rapid deposition rates

- Compact agile head,ideal for complex curvatures, limited space and low payload robots

- ‘Plug and Play’ head connectivity - head modules can be quickly replaced to suit different process requirements and maintenance

- Precise dynamic temperature control. Ultra-fast heat up and cool down response.

humm3® - intelligent heat for composites

humm3® technology is a high power, flexible, controllable heat solution for Automated Fiber Placement (AFP), Automated Tape Laying, Filament Winding and other composites applications. It is a sophisticated, pulsed light solution using three pulse parameters to hit target temperatures almost instantaneously.

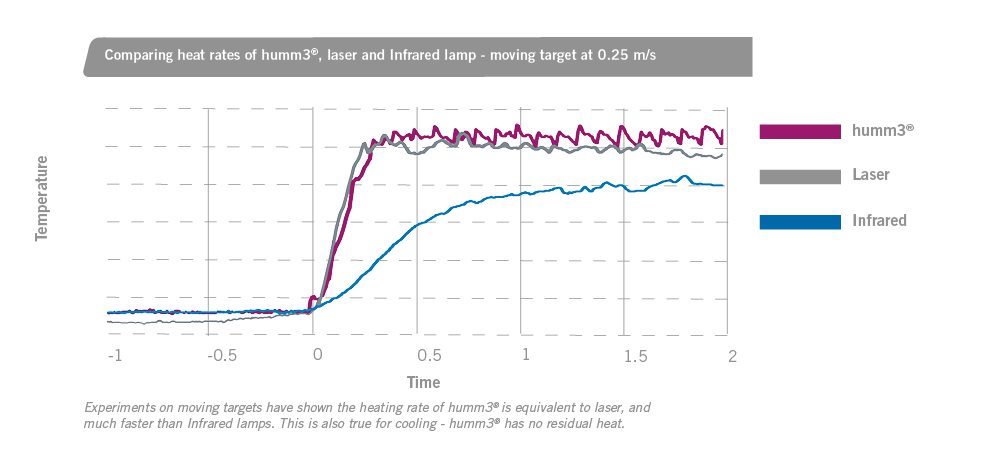

Noblelight’s humm3® technology delivers homogeneous, highly controllable heat to the process area, over a wide range of temperatures at rapid process rates. It’s instantaneous temperature ramp-up and cool down is ideally suited to processing complex parts using dry fibre and thermoplastic composite materials.

humm3® delivers the power that was previously only available from a laser, but with a much-reduced safety burden and without the costs associated with a laser safety enclosure. humm3® also offers scalable heated widths, with the largest heated width currently in service being 300mm. Wider widths are possible, which can greatly improve material deposition rates.

Benefits

Technical data

- Heat time/temperature equivalent to laser

- Very precise three parameter control

- Digital control system that responds to process speed

- Scalable heat zone size

- Energy to achieve high temperatures at fast process speeds

- Can be fully integrated into a dynamic robotic production cell.

Comparison of technologies

Selecting the right tool for your process

Introducing our new product families:

humm3® discovery and humm3® enterprise .

humm3® discovery is ideally suited to research and development, whilst humm3® enterprise is intended for integration and industrial work.