Users of UV LED flexo inks report significantly faster production speeds compared to existing UV curing technology. Additionally, UV LED curing systems offer more press uptime due to their significantly longer life, instant on/off capability, reduced maintenance time, and faster changeovers. UV LEDs operate up to 10 times longer (10,000+ hours) than medium pressure mercury arc UV curing systems. The instant on/off capability of UV LEDs means no more waiting to restart a press or deal with shutters as is required with arc UV lamps. Faster changeovers via flexible controls and curing adjustments such as wavelengths, working distance, dimming level (UV energy output) are possible with UV LED curing. All of these factors contribute to increased uptime resulting in higher production rates.

6 Ways UV LED Curing Improves UV Flexo Label Converting Processes

Improving label converting processes is an ongoing challenge given how hard it is to keep up with the latest technologies. UV LED curing technology has made significant inroads into many printing processes and now offers valuable benefits for narrow web flexographic (flexo) printing and overprint varnishing (OPV) for labels, tags, flexible packaging and shrink sleeve packaging applications. If you already have medium pressure arc lamp UV curing on flexo presses, then read on to learn about the benefits of retrofitting existing presses with UV LED curing technology.

6 Process Benefits of UV LED Curing Over Medium Pressure Arc Lamps

UV LED curing systems operate at much cooler temperatures than traditional UV curing making it possible to run heat sensitive materials without deforming them. Dimming controls mean you can dial in exactly the UV energy required for changing process needs. In addition to less product waste, this increased process flexibility and control can expand your flexo production capabilities to a wide selection of substrates to deliver higher press utilization. Retrofitting UV LED to existing presses can provide further flexibility for running combination print jobs, curing opaque whites and dense blacks at high speeds, or where improved adhesion is required, and even in combination with existing mercury arc UV lamps. Press operators can easily move the UV LED curing units to different print stations for additional job flexibility.

The smaller form factor of UV LED curing systems makes them easy to retrofit onto existing narrow web converting production lines and flexographic printing presses. In addition to their inherently small form factor, their low cooling and exhaust air requirements means there are no bulky and noisy external fans. UV LEDs need cooling, but it’s done using either internal muffin-type fans or water cooling. There is no need for shutters, and heat management and light shielding is greatly simplified.

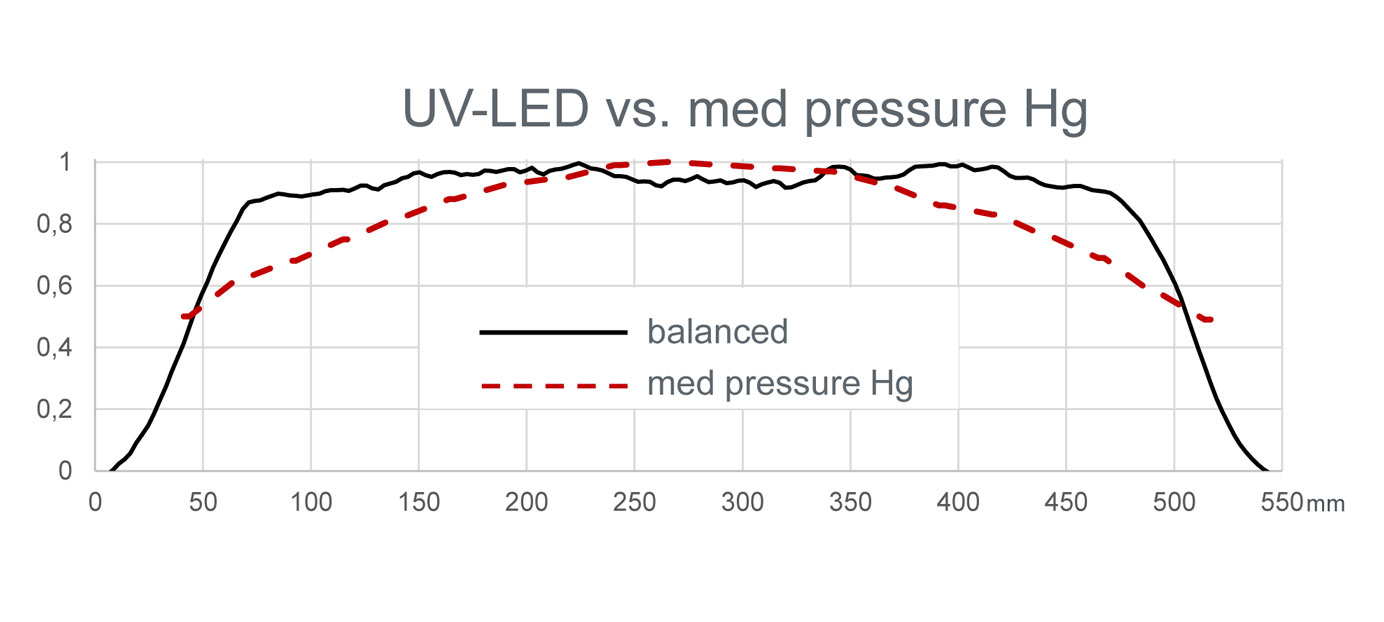

UV LED curing technology offers better uniformity across the print width, as shown in the graph. In addition, UV LED output degrades at a much slower rate over their lifetime compared to medium pressure mercury arc lamps which degrade by about 15 to 25% after only 1,000 operating hours. So UV LED curing provides a more reliable and stable process resulting in more consistent print results.

UV LED curing offers significantly lower press operating costs compared to traditional UV curing due to energy savings, fewer consumable parts, and lower maintenance costs. UV LEDs typically use about 30 – 70% less energy compared to traditional UV curing. Not having to keep consumable parts like lamps, ballasts, and reflectors on hand also provides costs savings. Finally, lower maintenance costs result from less labor time spent replacing lamps and cleaning/servicing other components such as ballasts, shutters, reflectors, and fans.

While not directly related to the process itself, process engineers designing and developing press improvements need to consider the working environment. Since UV LEDs don’t generate ozone (traditional UV lamps generate ozone from their short-wave output around 180 nm to 220 nm)and contain no mercury, the working environment is safer for press operators and there is no need to deal with hazardous waste disposal of lamps. In addition, the press floor working environment is much quieter because exhaust blowers are not needed.

Widely available UV LED curable flexo inks, coatings, and adhesives

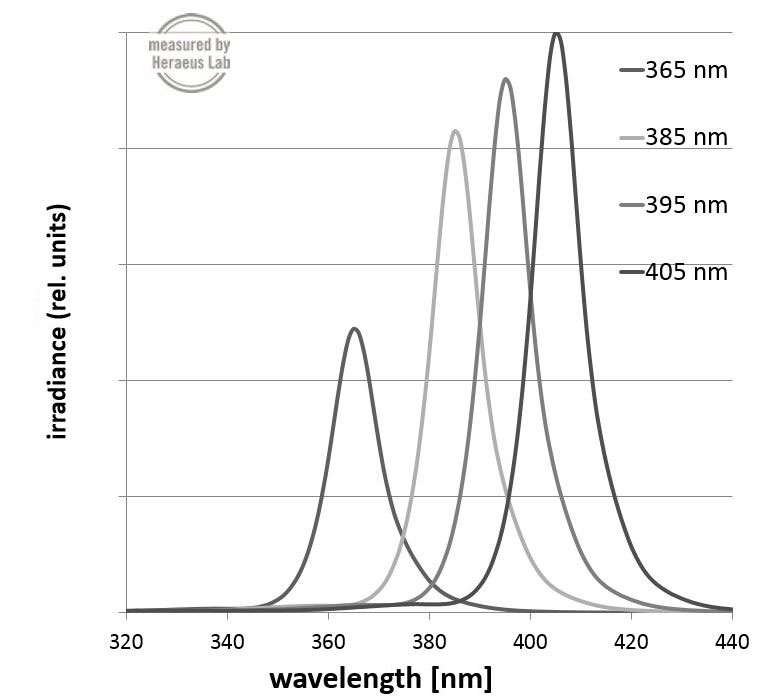

Unlike traditional UV curing which has a broad spectrum output, the output of UV LEDs for curing applications is currently available in one of three narrow, nearly monochromatic, wavelengths – 365, 385, and 395 nm.

While this means less wasted output (unneeded or unusable wavelengths), it also means formulators needed to reformulate chemistries to make them responsive to these specific wavelengths while still delivering the specific requirements for narrow web flexo printing, OPVs, or PSAs.

The longer wavelength output of UV LEDs means they can penetrate deeper enabling better cure of thicker pigmented inks such as opaque whites and blacks with better adhesion to the substrate.

New possibilities with UV flexo

UV LED flexo inks, OPVs, and PSAs are readily available from most suppliers. More recently, ink suppliers introduced low migration UV LED flexo inks and coatings suitable for food and pharmaceutical packaging and label applications with print speeds in excess of 500 fpm. This opens up an entirely new market for narrow web converters and flexographic printers – short run flexible food and pharmaceutical packaging which demands quick turnaround. And at least one ink supplier recently introduced flexo inks suitable for either UV LED or traditional UV lamp curing making it especially easy to combine the curing technologies on one flexo press.

Next steps

First, begin learning more about UV LED curing technology, equipment providers, and possible chemistry formulation partners to understand how UV LED curing fits into your operations and onto your flexo presses.

Second, build relationships with experienced providers who can help you develop reliable and flexible UV LED curing processes via lab testing and on-press trials . You’ll need partners who can help you assess the best option for incorporating UV LED curing into your narrow web flexo processes.

Start learning more now by clicking the following:

Optimizing Flexo Label Production: Upgrading Traditional UV with UV LED Curing – Upgrading traditional UV curing equipment on flexographic presses to UV LED curing technology offers significant process benefits for label and tag production. But it’s prudent to learn what the options are and how each can optimize your label production processes before selecting a UV LED curing system provider.

Guide to Retrofitting a UV Flexo Press for Productivity Advantage: UV LED Equipment Features to Consider – Considering an upgrade to UV LED curing technology on your flexo press can be daunting. This guide helps you navigate the UV LED curing equipment features that will deliver higher press productivity.

UV Curing for Flexo Comparison Chart: Traditional UV versus UV LED - When considering UV LED curing for your flexo printing and label converting processes it’s helpful to compare your existing mercury arc UV to UV LED curing technology. This chart provides concise and easy comparisons, the characteristics of each, and process design considerations for typical narrow web flexographic label converting processes.