Many industries require clean, disinfected water for various purposes. Such purposes are, for example, rinsing and cleaning, sample analysis or cooling. But production processes in the food and beverage, cosmetics, chemical, semiconductor and other industries also depend on clean water.

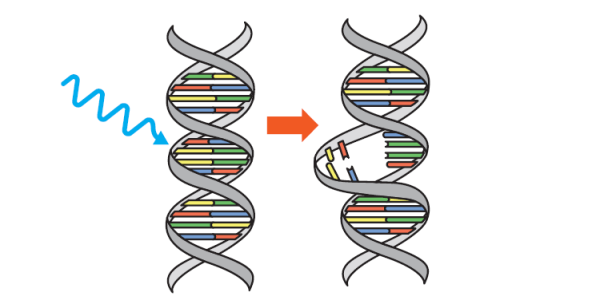

High-energy UV light is an established eco-friendly method of process water treatment. It does not require the addition of chemicals such as chlorine. Special UV lamps not only destroy bacteria, viruses, parasites and fungi. They can also break down harmful total carbons (TOC) in certain processes.

Microorganisms cannot build up resistance to UV light like they can to chemical water treatments. In fact, UV light inactivates chlorine-resistant pathogens, such as cryptosporidium.