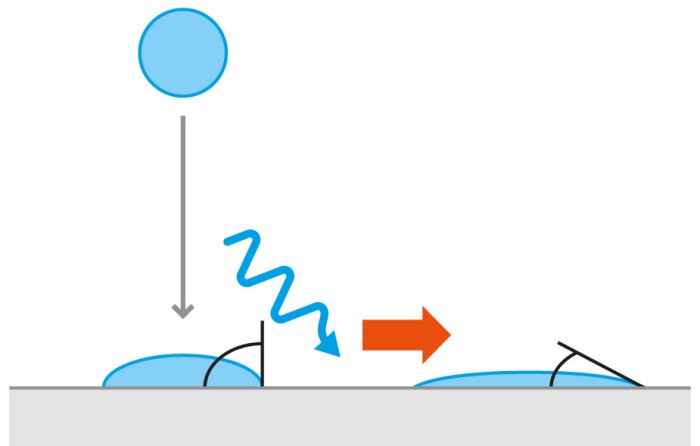

High-energy UV photons are able to break up molecular organic bonds at and on surfaces.

This UV oxidation process cleans the surface of contaminants.

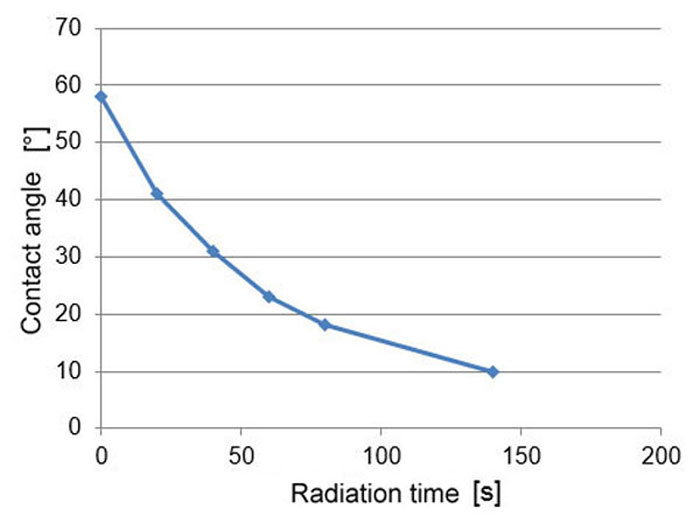

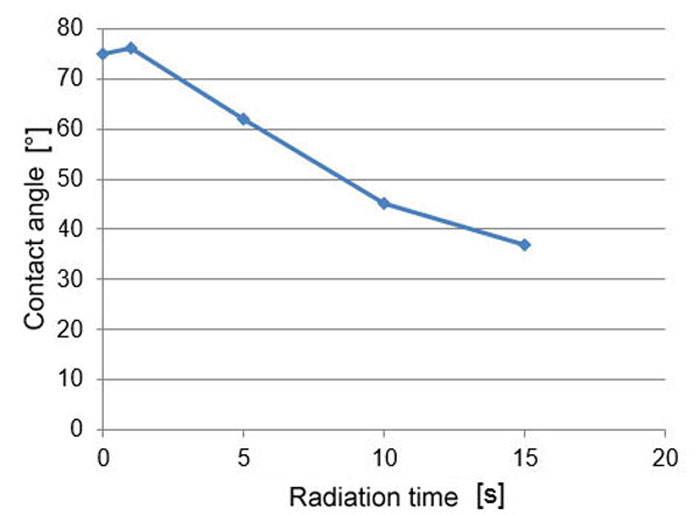

It also leads to the introduction of functional groups such as hydroxyl, carbonyl or carboxyl groups which increases the surface energy of a surface which improves both wettability and adhesion.