An estimated 90% of industrial heating processes in Europe are operated with non-electrical energy sources (gas, coal, oil). Electrical process heating methods use energy more effectively and in a more targeted manner. The use of energy through electricity offers the possibility of making the CO2 footprint particularly favorable by selecting green electricity.

Why we are sustainable, energy efficient and green

UV, IR and Flash for Environment, Carbon Footprint and Green Future

Climate summits, Fridays for Future, students, politicians and eco-activists are not the only ones worried about the future - Excelitas Noblelight also makes an active contribution to more sustainability and energy efficiency. UV, infrared and flash technology accept the challenge and contribute to innovative and sustainable processes.

Special lamps from Excelitas promote both: renewable energy production and saving energy, as the following examples show. It is therefore worth examining industrial processes in detail to make them more energy-efficient - and thus more cost-effective - through the use of productive light.

How to reduce the CO 2 footprint with electrical infrared systems

How do IR, UV and Flash help to increase the energy efficiency of your system?

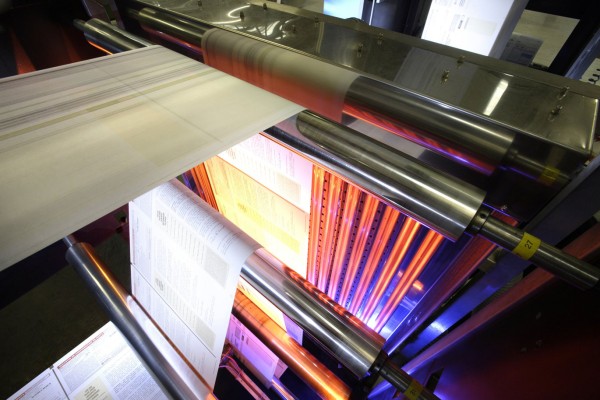

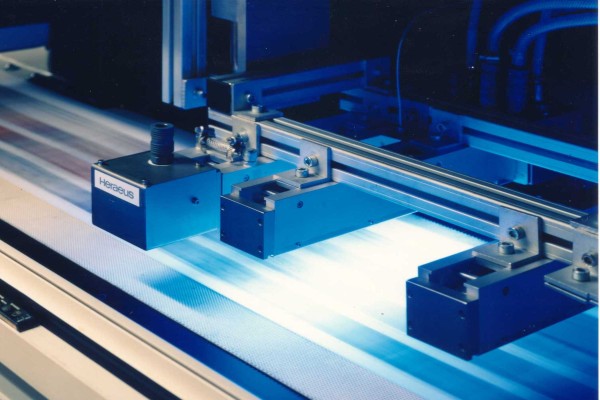

Modern infrared, UV curing or flash technology can be focused precisely at the product and does not require standby operation like some conventional technologies. This precise coordination saves unnecessary energy losses to the environment.

- Infrared and UV radiation do not require a transmission medium

- Radiators make heating and drying processes more energy efficient

- Fast reaction times – energy only when it is needed

What do flash, UV and infrared contribute to the generation of alternative energies?

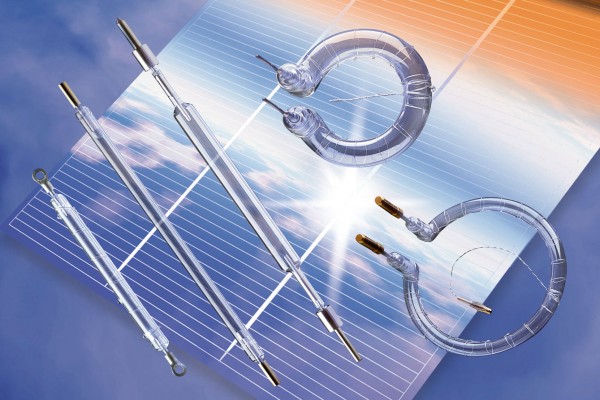

In the production of solar cells, solar simulation using flash lamps ensures better quality. Infrared emitters dry the anti-reflective coating of the solar cells in a vacuum as well as the coating of the blades of wind turbines. Batteries and lightweight materials for e-mobility require completely new manufacturing processes - innovative infrared, UV curing and flash systems contribute to this.

UV, infrared and flash technology for the manufacture of alternative products

When the parts of a car are joined together without additional glue, they are easier to reuse later. Infrared heat and UV curing make this possible. Plastic made from corn starch is used, for example, to produce blisters or trays for chocolates. The thermoforming of such plastics benefits from precisely adjusted infrared wavelengths.

Sterilizing surfaces, conveyor belts and packaging with UV light and infrared heat helps reduce chemicals and preservatives.

ENERGY EFFICIENT AND SUSTAINABLE INFRARED - UV - FLASH - PRODUCTS